Jung Process Systems Supplies Replacement Pumps in No Time

The failure of a pump can have undesirable consequences, especially in food processing. If production comes to a halt, delivery promises cannot be met and there is a risk that products will spoil. A replacement is needed as quickly as possible – a job for Jung Process Systems GmbH, based in Pinneberg near Hamburg, north Germany. Thanks to a high level of in-house production, the pump manufacturer can deliver replacement pumps in no time.

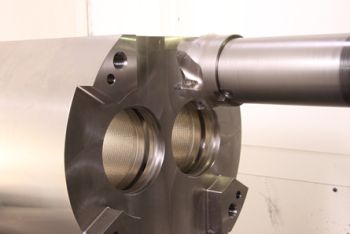

In-house manufacturing guarantees quick delivery times and a high degree of flexibility for custom orders (Image: Jung Process Systems)

Jung Process Systems GmbH manufactures hygienic twin screw pumps under the brand name Hyghspin. Hyghspin pumps comply with hygienic design standards and are primarily used in the food industry. The majority of customers are in the dairy industry, the large and varied fine foods sector and the beverage industry.

Almost all manufacturing, including the production of all components, takes place in house. "We aren t dependent on parts suppliers and we can switch over our production activities very quickly. This is unusual in our sector," says Anke Jung, Managing Director of Jung Process Systems. "It means we can react immediately in an emergency." But even in normal circumstances, Jung Process Systems offers comparatively fast delivery. On average, a complete pump unit is manufactured within four weeks. "We have much shorter delivery times than the market average," says sales manager Henning Grönwoldt-Hesse.

New sales partners

The fact that the pump manufacturer, formed five years ago from family-owned company Jung & Co. Gerätebau GmbH, delivers quickly and on time is reflected in its sales. "We are seeing steady growth rates in double digits. The biggest growth market is currently Germany with a rise of over 50%," says Anke Jung. The company has achieved considerable growth in South America. To expand business in northern Europe, the UK and the Middle East, new representative offices are to be established there over the next few months. Language problems are unlikely: support can be provided in English, French, Spanish and Portuguese.

Source: Jung Process Systems GmbH