Intelligent Pump Monitoring for Chemical Engineering from Colfax Fluid Handling

Colfax Fluid Handling introduces it´s new intelligent platform for condition and operation monitoring. The platform was developed specifically for pumps that are used in operationally-critical and environmentally-sensitive applications in chemical engineering.

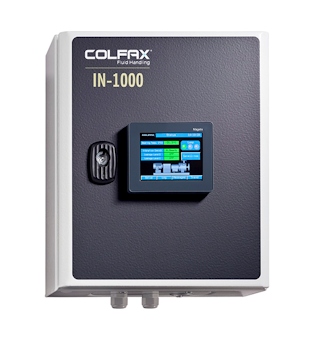

The IN-1000 master module displays notifications and sensor values from all pumps and forwards them over the Internet, for example, to the master control panel, computers, smartphones, or tablets. (Allweiler GmbH)

IN-1000 improves safety while reducing operating costs. The core of the system is a software program developed by Allweiler.

The new Smart Platform can be used in straightforward condition monitoring to complex monitoring activities. This includes operational monitoring of several pumps for simultaneous fulfillment of safety and operating-cost requirements. Examples include monitoring of pressure, temperature, leaks, and vibrations. The system may also be expanded with standard industrial sensors.

Operations in these cyber-physical systems are monitored continuously and with full automation. Logging of activities permits subsequent evaluation. If unusual operating conditions appear, they are announced immediately and shown on a graphics-capable color display. Ethernet connections provide for communications with the master control panel. Maintenance personnel, for example, can use apps for remote access from any smartphone or Internet-connected computer. With this development, megatrend Industry 4.0 has arrived in the world of pumps, with Colfax/Allweiler implementing the Internet of Things for its products. Depending on configuration, the Smart Platform will automatically respond to pump-related events, such as by switching to another pump. Because of these capabilities, maintenance and repairs can be planned in advance, there are no unplanned production downtimes and maintenance intervals can be extended.

"The Smart Platform helps to reduce overall costs and is more economical than similar systems. When it comes to sensitive operating conditions, like those encountered with environmentally hazardous or explosive fluids, the increased safety is at the forefront," says Gunter Connert, Sales Manager for Germany at Colfax Fluid Handling/Allweiler. The system can be used with many Allweiler pumps. Retrofitting is also possible.

Source: Colfax Corporation