Innovative Coating Minimises Life Cycle Costs

For water-supply pumps the energy costs make up about 84 % and are thus the largest part of life cycle costs. With the innovative "Ceram CT" coating of the pump expert WILO SE the pumps efficiency can be increased so that the energy costs and thus the entire life cycle costs can be considerably reduced.

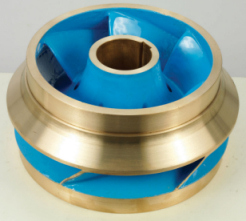

The innovative "Ceram CT" coating is applied at those parts of the impellers and stage housings that come in contact with the fluid. Due to the low surface roughness, the pump s efficiency is increased by 2 %. (Picture: Wilo)

"Ceram CT" is a coating with KTW approval which was particularly designed for borehole technology. It is applied at the impeller blades, the inner contour and inside the stage housing. The "Ceram" coating is characterised by a low surface roughness. The pump s efficiency is increased by approx. 2 %. Moreover, it can be an efficient protection against ochre formation. Furthermore, components coated with "Wilo Ceram" have a high wear resistance which extends their service life considerably. At the same time, continuous effort for maintenance and repair is reduced. This procedure is possible for pumps in the 8 inch range, K 85, NK 86 and NK 87 and all borehole pumps larger than 8 inch.

The following example shows which savings can be achieved with the coating: If a "Wilo-EMU KM1301" borehole pump is coated with "Ceram CT", the pump s efficiency is increased from 79.4 % to 81.4 %. While the motor efficiency remains the same, the total efficiency is increased by 1.8 %. At the same time the motor s power consumption is reduced by 7 kW. Given an annual operating time of 7,300 hours and an electricity tariff of 0.15 Euros/kWh, there are annual energy cost savings of 7,665 Euros, thus the additional costs for the "Ceram CT" coating pay off already after 38 days.

Since the coating can also be applied afterwards, reworking the hydraulic system of a current pump also pays off after a very short time. In that case the amortisation period is 83 days. Even an early replacement of a still functioning old pump by a new unit coated with "Ceram CT" pays off. According to an example calculation from Wilo, the purchase price of a new pump is approximately 23,000 Euros, but brings about an annual electricity cost saving of 15,330 Euros. Thus the investment pays off already after one and a half years. So in this example energy cost savings by using a new pump coated with "Ceram CT" amount to 153,000 Euros throughout a life cycle of 10 years – and here, an increase of electricity costs is not even included! Thus the "Ceram CT" coating contributes decisively to reducing the life cycle costs of borehole pumps.

Source: WILO SE