Innovative Bearing with Split Bracket

ALLWEILER AG has taken the proven split bearing design to a new level. The new bracket saves money by simplifying installation procedures and keeping pumps in service significantly longer.

Source: Allweiler

It achieves this by making them less susceptible to external forces, especially those commonly encountered in ship applications. Allweiler will display the new “split bracket” design at SMM in hall 04 (booth EG.232).

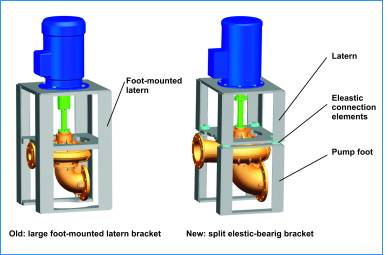

The new design eliminates the limitations previously encountered during installation and also simplifies the installation procedures. The split bracket disengages the pump and motor from the ship structure. Instead of a large and rigid foot-mounted lantern bracket, the new design employs a drive bracket with elastically mounted feet, with the connection itself facilitated by highly durable elements with a long service life. As a result, the pump has the ability to yield to external forces and balance out the forces that act on it. The split bracket permits neither twisting nor resetting forces to enter the piping and the ship structure.

Manfred Britsch, the development engineer at ALLWEILER responsible for this product, describes it this way: “We conducted a large number of investigations in our test lab before releasing this product for sale. We investigated oscillation behavior and resonance under dynamic operating conditions over the course of several months. But we paid special attention to the elastic connection elements. Each test was conducted both experimentally and theoretically.”

The split bracket design exhibits a whole range of benefits over single-piece brackets. The natural frequencies of the split bracket are much higher than the structural natural frequencies of the single-piece bracket. The overall design is affected much less by the tilting of ships in which the pump is installed. As a result, the pump is able to continue working without any changes even under heavy seas and during the rapid positional changes associated with those conditions. But the design is simultaneously about 30 percent lighter because the split bracket achieves the same stability and durability with narrower wall and material thickness. Furthermore, forced distortions (which can lead to alignment errors on the coupling) caused by forces coming through the pipes or by hydrostatic pressure forces are significantly lower. Finally, in many cases the elastic bearing elements make the reaction forces and twisting in the split bracket much lower than those found in the one-piece foot-mounted lantern bracket.

These improvements give ship owners important financial benefits during both installation and operation. Installation goes faster and with lower costs because the danger of twisting is reduced and alignment errors can be detected faster. In addition, the oscillation-optimized installation of the pump produces greater operational safety. This is especially beneficial under unfavorable conditions, like during heavy weather at sea. Overall, the split-bracket gives the pump a longer service life by reducing the effects that external forces have on the running pump and by lowering structure-borne noise, which results in smoother running.

Source: ALLWEILER GmbH