Industrial Ethernet Allows Technical Support From a Distance

Vinterteknik is a Swedish company developing snow cannon and irrigation systems. They use Emotron variable speed drives for controlling the pumps included in their solutions, in order to offer smooth operation and reduced energy costs.

In this case, the long distance and the difficult terrain between the control station and pumping station offered a challenge. The solution was remote control of the variable speed drives over the Internet.

Systems for supplying snow and water

Vinterteknik Sundsvall AB designs, develops and installs complete solutions for supplying artificial snow, including the related pumping systems. The seasonal fluctuation is compensated by also offering irrigation systems for football pitches, golf courses, parks etc. Emotron variable speed drives are used for controlling the pumps.

Distance and topography was a challenge

Järvsö skiing centre in Sweden is one of Vinterteknik’s customers. They needed to supply water to their snow cannons from a river located 3 km away, and control the pumps in the pumping station by the river from the control station at the skiing centre. The long distance and difficult terrain offered a challenge. Using special cabling would cause high material and installation costs as well as signal attenuation problems. In addition, it would not provide redundancy in case of damage to the cable, which was a requirement for the customer. They also requested a user-friendly operator interface. Vinterteknik turned to Emotron to suggest a suitable solution.

Variable speed drives control the pumps

In the pumping station, two Emotron FDU variable speed drives control 250 kW motors driving two pumps. In the control station, three pumps are used for boosting pressure up to the snow cannons located higher up on the ski slopes. The pumps are controlled by one Emotron FDU variable speed drive and two Emotron MSF softstarters.

A drainage valve is used to release water from the pipe when the snow cannons are not in use in order to avoid blowing the pipes if the water freezes. This valve is also controlled via the web server interface. An alarm function ensures that the variable speed drives can only run when the valve is closed.

Remote access and redundancy

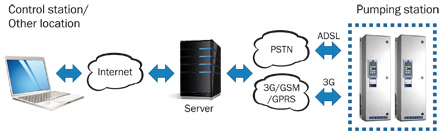

When choosing communication solutions, it was obvious that it would be difficult and expensive to use standard cabling. The suggestion from Emotron was therefore to open up secure remote access to the pumping station over the Internet. This was possible thanks to the Emotron variable speed drives supporting communication via industrial Ethernet. The Internet is non-deterministic and therefore mainly suitable for logging and configuration purposes. However, in non-time critical applications such as this it can also be used for control.

The variable speed drives are equipped with Anybus CompactCom plug-in modules from HMS and communicate via the open protocols Modbus/TCP and HTTP. An integrated web server using the HTTP protocol extracts and presents parameter information from the variable speed drive, and provides access to the connected unit via a web browser, for example Internet Explorer. Monitoring and control can then be carried out from a PC with a VPN client. No additional software is required.

For additional security, it was decided that communication would take place primarily via the ordinary telephone network (PSTN) over ADSL, with the option of using wireless 3G communication as a backup. The DR-250 router from Westermo automatically switches over to the 3G network in case the telephone network is interrupted.

Tailored web pages for user-friendliness

Emotron developed tailored web pages for monitoring and controlling the snow cannon application, giving easy access to selected process parameters such as reference value, speed and current. All process values are updated every five seconds and are presented in SI units, for example, bar for the reference pressure. This makes the information easy to interpret. The operator can start and stop the operation with just a push of a button, and can easily set a new reference value for the water pressure.

Support from a distance saves time and travel

Since the system is connected via the Internet, monitoring and configuration can be done from anywhere in the world. The only thing required is a computer with a web browser and VPN software. This also opens up the option of remote support. Technicians from Emotron or Vinterteknik can access all parameters by connecting to the variable speed drives via a VPN tunnel and quickly assist in troubleshooting or configuration without being on site.

"This offers several advantages," says Rolf Härén at Vinterteknik. "Customer service is improved, downtime is reduced, and cost and environmental impacts from travelling are eliminated."

To be implemented in more skiing centres

André Rowéus, technical specialist in communication solutions at Emotron, sees great potential in the industrial Ethernet:

"We will see a strong increase in usage. The technology allows remote configuration and fast and accurate control. It enables systems to exchange large amounts of information quickly while also providing a user-friendly interface. By analysing collected data from the application, customers can optimise their processes and eliminate bottlenecks. Faults can be located and corrected faster, and redundant network topology improves safety."

Rolf Härén at Vinterteknik is happy with the solution: "Response times are short, despite the fact that we are running over the Internet, and the demands for secure communication and user-friendliness are fulfilled. We plan to implement the solution in other skiing centres."

Picture: The Emotron variable speed drives communicate via Ethernet using Modbus/TCP and HTTP. In this case, communication is primarily done via the ordinary telephone network over ADSL, with wireless 3G communication as a backup.

Source: CG Drives & Automation Sweden AB