Increasing Energy Efficiency and Performance with Eaton’s Variable Speed Drive Hydraulic Pump Solutions

Power management company Eaton is merging its capabilities in the electrical and hydraulics space to offer machine and system builders variable speed drive (VSD) pump solutions that allow for improved machine performance and energy savings of up to 70 percent - depending on machine duty cycle.

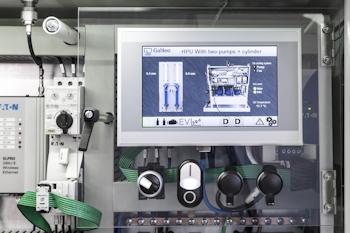

The hydraulic power unit is controlled by Eaton’s HMI/PLC, which communicates with common fieldbus systems as well as SmartWire-DT. (Image: Eaton)

The fully integrated electro-hydraulic system is widely scalable. It comprises a broad range of vane and piston pumps, filters, frequency inverters, control and switch gear as well as Eaton’s innovative SmartWire-DT intelligent wiring technology. Suitable applications range from the machine tool sector to casting, steel or press applications, where users benefit from extended machine life by lowering heat generation and improved operator safety and comfort by reducing pump noise levels.

Combining the power density and proven performance of Eaton’s pump systems with the smart control functionality of VSDs, the system can achieve power-on-demand in a more energy efficient way than a conventional system with proportional valve technology. Instead of operating constantly at 1500 RPM or 1800 RPM (depending on region), Eaton’s variable speed drive pumps can be controlled to match the load requirements of the current duty cycle via intelligent control – as a result energy waste can be eliminated.

By integrating IP67 SmartWire-DT I/O modules, and thus taking SmartWire-DT outside the control panel, the installation of sensors and actuators to monitor for example vertical movement of the cylinders, or temperature and pressure of the pump system is easy, fast and flexible. As the IP67 modules can be provided as units with just a single I/O, machine builders are given even more freedom of choice in terms of architecture. They provide them with significantly simpler systems from design to assembly – the construction of new systems and the modification of existing machines can be carried out with less cabling effort and with reduced use of materials.

The entire hydraulic power unit, which is controlled by Eaton’s HMI/PLCs, can allow for a high degree of scalability as they come with an Ethernet interface and also communicate with the common fieldbus systems as well as SmartWire-DT. With SmartWire-DT integrated, the HMI/PLC connects motor protection or pilot devices without conventional point-to-point wiring. Thus, the effort and time for wiring a machine is reduced by up to 85 percent.

SmartWire-DT combines and powers up to 99 stations over a length of over 600 metres. As the technology is easy to use, it significantly reduces wiring errors and helps machine builders where qualified labour is in short supply as the training for assembly with SmartWire-DT is shorter and does not require wiring experience.

The hydraulic power unit features remote connectivity supporting preventive maintenance as well as machine diagnostics and control functionalities. It also comprises solutions from Eaton s Filtration Division, such as the TEF 55 return filter and NBF 40 breather filter. This ensures high purity of fluids for a safe and efficient application process.

Source: Eaton Corporation plc