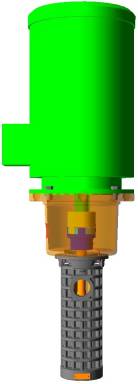

Immersed Screw Pump for Oil

Allweiler AG’s introduction of the ALLUB®-RUV pump series expands their selection of vertically immersed pumps for supplying lube oil and hydraulic oil. The new pump combines the proven RU pump (from lift engineering) and a pump bracket with an elastic gray-cast coupling for installation of an IEC motor.

New vertically immersed pump ALLUB®-RUV for delivery of lube and hydraulic oil

And since it is designed without a shaft seal, this pump is maintenance free and extraordinarily durable.

The new ALLUB®-RUV is ideal for use in any industry where mineral-based and synthetic lube oil, hydraulic oil, and other similar media must be moved efficiently. This triple-spindle, self-priming screw pump is de-signed for vertical installation in the oil container. Depending on the size of the pump and motor, these pumps can be used in tanks that are be-tween 400 and 1000 millimeters deep. Since the pump has no shaft seal, the sealing elements do not require any costly and labor-intensive main-tenance. The main arbors are hydraulically driven. The thread flanks are virtually free of loads and are not subject to wear. The new pump set is especially durable and maintenance free.

A strainer round plate is attached directly to the rotor housing on the suction-side in order to provide protection from mechanical contamina-tion. This is an effective way to protect the strainer round plate from damages that may occur during assembly or disassembly, for example. An external pressure-limiting valve in the piping prevents an excessive pressure condition. The ALLUB®-RUV is suitable for operation in poten-tially-explosive environments and complies with the requirements of the EC explosion protection directive 94/9/EC (ATEX 100a) of the device class II, categories 2G and 3G and temperature classes T1 to T4.

The pump bracket contains motor and pump centering rings for installa-tion on a container sole plate. The centering rings ensure that the pump and motor shaft always align precisely, thereby eliminating the need to fine-adjust the coupling.

ALLUB®-RUV is available in various sizes and with several different screw-pitch angles. This makes it possible to finely graduate the flow rate over the entire operational range. The maximum flow rate is 850 liters per hour at a maximum pressure of 16 bar; the maximum viscosity of the pumped liquid is 750 mm²/sec.

Source: ALLWEILER GmbH