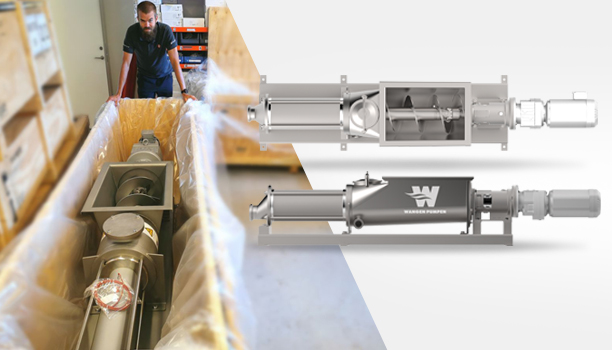

Hygienic Progressive Cavity pump ready for hard work in Norway

The latest delivery of an innovative Wangen hygienic pump to Froster AS still creates awe and wonder for Gaute Løvlien! (Image source: Pumpenfabrik Wangen GmbH)

Froster AS will install this stainless steel WANGEN pump under a decanter to transfer filter cake containing fish bones and up to 40% dry solids for further processing.

Our faithful customer chooses WANGEN pump KL50RL due to its hygienic design:

- Sealing arrangement in hopper designed to ensure effective cleaning-in-place (CIP)

- Hopper designed without acute angles to prevent product sedimentation

- CIP connections in hopper enable easy and thorough cleaning

- Self-draining discharge flange

- Easy serviceability

- Cost-effective pumping solution

WANGEN PUMPEN's Regional Sales Manager, John Booth appreciates the profound technical knowledge that Froster AS has of the strict hygiene regulations that apply to the fish processing industry.

For over 20 years, Froster AS successfully supplies Wangen Pumps to the Food &Beverage, Biochemical, Anaerobic Digestion and Wastewater Industry in Norway!

Source: Pumpenfabrik Wangen GmbH