Hyghspin Pumps Specially for Pharmacy and Cosmetics Applications

Product and process safety requirements in the pharmaceutical industry are extremely high. Consequently, pharmaceutical companies declare challenging requirements to their production and laboratory facilities. Frequent focus is put on sterile production which is reproducible into detail.

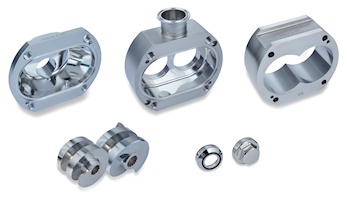

Hyghspin Components Ra ≤ 0.4

Key aspects are as follows: simple cleaning of all process components, i.e. including the pumps used, and gentle product transport.

Hyghspin twin screw pumps comply in detail with both of these essential requirements of the pharmaceutic and cosmetics industry. They are constructed according to the criteria of the Hygienic Design and consist completely of stainless steel with a surface finish of Ra ≤ 0.4, if required. The mechanical seals are completely located in the flow area, the elastomers are FDA approved. The pumps are gap-free and without any dead space and can be completely emptied in order to avoid contaminations by means of product residues or intermixtures. They are CIP-capable and can be sterilized up to a temperature of 145°C.

Hyghspin pumps are used, for instance, for the production of creams, ointments and liquid soaps. Hyghspin pumps work with non-contact axially operating feed screws facilitating relatively low product flow speed through the pump, without deviation of flow direction, thus avoiding foaming of liquid soap during transport and achieving a gentle, nearly pulsation-free feeding at constant high suction capacity. In the cosmetic industry abrasive product constituent parts are also very often added. Thanks to modern drive technology only little heat gets into the product. The speed range of

5 – 120 Hz offers a high flexibility and economical appliances for products of different viscosities.

Source: Jung Process Systems GmbH