Hydraulic Institute Releases new Rotodynamic Pumps – Guideline for Dynamics of Pumping Machinery (ANSI/HI 9.6.8–2014)

The Hydraulic Institute has announced the release of the new Rotodynamic Pumps – Guideline for Dynamics of Pumping Machinery (ANSI/HI 9.6.8–2014).

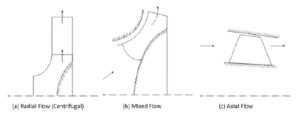

The new guideline describes and recommends the means to appropriately evaluate pumping machinery construction attributes and relevant site characteristics in order to determine the effects of dynamic performance on equipment life and reliability. It describes and recommends various levels of detailed evaluation and validation that are commensurate with the degree of equipment uncertainty and application risk. The document also provides guidance for the pump industry pertaining to the following topics:

Dynamic perturbations may result in the excitation of structural resonance in any installation. With the trend towards increasing use of variable speed drives within pumping systems, avoiding this excitation of structural resonance has become increasingly more difficult. It is therefore important to ensure that the potential problems caused by high vibration are properly addressed and mitigated during the design phase.

Further development of the analytical tools and techniques used to identify these issues has also dramatically increased. However, it is not always clear which tools are available and how to use them in various applications across various markets and diverse products. Equally the range of preventive measures remains quite diverse, ranging from simple to complex. The associated expense can be small to relatively large when compared to the cost of the equipment. In all cases it is better to avoid a problem than to fix it after the fact.

This guideline:

- Includes what analysis is appropriate to specify or utilize for proper evaluation of new pumping equipment, prior to design or field installation

- Explains what analysis is needed to make an accurate assessment of existing pumping equipment installed in the field

- Ensures that any upgrades, rerates, or field modifications are done in a manner that will validate contemplated equipment design and field modifications

- Recognizes the economics associated with analysis to different Level requirements

- Prepares readers for dynamic characteristics of pumping equipment that might be significantly influenced by the installation, including piping configuration, mounting arrangement, or drive system

- Explains how to utilize the Decision Matrix that includes the Uncertainty Values, Risk Number, and RUN Value to arrive at the suggested Level of analysis

This standard is now available for purchase in the HI eStore

Source: Hydraulic Institute Inc.