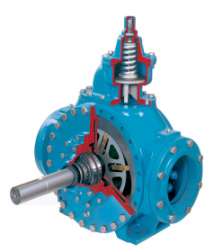

HXL Sliding Vane Pumps Quickly Evacuate Terminal Storage Tanks

Blackmer announced that its HXL sliding vane pumps have the unique capabilities to quickly and efficiently evacuate product from large liquid storage terminals. In today’s economic environment, efficient liquid terminal operations depend on the ability to react quickly to market opportunities to handle a wide variety of products.

Blackmer

High capacity HXL pumps handle large volumes of non-corrosive liquids, from thin solvents to heavy oils and molasses. Strong suction lift capability efficiently transfers these products from barge or ship into storage tanks while efficiently stripping both suction and discharge lines to minimize product loss. Self-adjusting vanes eliminate slippage caused by normal wear, thus maintaining flow rates. HXL pumps are also self-priming so they are always ready to operate without time-wasting priming routines, while an internal relief valve protects against excess line pressure.

A major benefit of Blackmer HXL pumps is significantly reduced maintenance versus other pumping technologies. For example, replacing sliding vanes can be accomplished simply and in a matter of minutes. Replaceable casing liners and end discs make rebuilding the pumping chamber easier and faster, too, without the need to disconnect the pump drive or system piping.

HXL models are available in 6, 8 and 10-inch ANSI flanged port sizes with operating speeds up to 350 rpm and maximum rated capacities of 755, 1228 and 2300 gpm (172, 279 and 522 m3/h), respectively. The ductile iron pumps can be powered with a standard electric motor or diesel engine through a commercial gear reducer.

Source: Blackmer