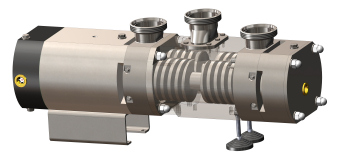

High-pressure Pump Manages Differential Pressures up to 50 bar

With the recently developed high-pressure HYGHSPIN 90DF, Jung is opening up market segments for twin-screw pumps that were previously normally reserved for other pump types.

The double-suction HYGHSPIN 90DF manages pressure differentials up to 50 bar (Image: Jung Process Systems GmbH)

In many areas of the food and beverages industry there is a distinct trend towards the use of pumps that are able to reliably manage higher pressure differentials. This trend is due not only to the higher friction losses caused by longer pipelines and increasing flow rates in the production plants but also to the pumping of generally higher-viscosity media that enable savings in terms of energy to heat the media. A further reason is the change in general consumer behaviour that has led to the increased use of heat exchangers in the production of foodstuffs in order to adapt product characteristics specifically to consumer requirements. In heat exchangers the flow rates are limited by the pressure loss. Larger flow rates therefore require higher pressure differentials. There is a comparable situation in the use of filtration units.

The new HYGHSPIN 90DF is ideally suitable for these demanding pumping tasks. As a powerful, externally mounted, hygienic design twin-screw pump, it transports the medium extremely gentle and is easy to clean. Fitted with double-acting mechanical seals, it is also safe to run dry and works with low pulsation, which has positive consequences for the service life of the total production unit. The double-suction 90DF model has two product inlets and one outlet, achieves discharge pressures of up to 50 bar and rounds out the high end of the HYGHSPIN product range. It is already successfully in operation with several international customers.

Source: Jung Process Systems GmbH