Flux Zone Separation for Barrel Pumps

Flux-Geräte presents the FP 430 S Ex, the first model of a new barrel pump series with improved explosion protection.

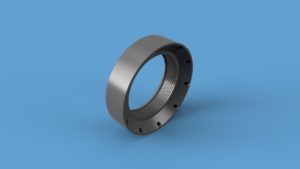

FP 430 S Ex (Image: Flux-Geräte)

The pumps give users the necessary safety when transferring media in explosion hazard areas - even in extreme cases.

Already in 1953, Flux-Geräte introduced the F 300 Ex to the market, the world s first explosion-proof barrel pump.

The Flux research and development department perform risk assessments and product monitoring for their devices at regular intervals. So new findings about an extremely rare ignition risk have led to the further improvement of the explosion protection of the Flux barrel pumps: Flux engineers have developed the Flux zone separation. The design measure separates the ball bearing in the upper area of the pump from zone 0. This causes natural ventilation of the area below the ball bearing and makes carryover of explosion hazard zone 0 due to an undetected leak impossible by design. At the same time, heavy sealing damage can be detected faster because transferred medium that rises can drain off.

Certified conformity

All Flux barrel pumps are examined by Physikalisch-Technische Bundesanstalt (PTB) and receive EC type examination certificates. The type examination certificate in compliance with the ATEX Directive 94/9/EC and standard DIN EN 13463 has also already been issued for the new explosion-proof barrel pump series - FP 424 S Ex, FP 425 S Ex, FP 426 S Ex and FP 430 S Ex. The first barrel pump of the new series, the FP 430 S Ex, will be available from October 2012.

Source: FLUX Pumps Intern. (UK) Ltd.