Effective Protection for Electric Motors and Loads by Siemens

The Simatic ET 200SP motor starter protects electric motors and loads. Siemens has designed it for higher performance, and added new versions and functions. Four adjustment ranges up to 5.5 kilowatts now make the motor starter particularly powerful.

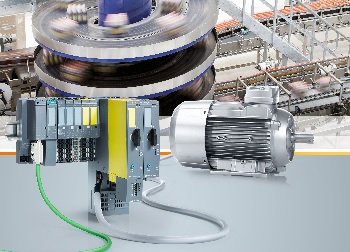

The Simatic ET 200SP motor starter protects electric motors and loads. Siemens has designed it for higher performance, and added new versions and functions. (Image: Siemens)

With the new fail-safe versions, there is now a wide range of standard and fail-safe motor starters for switching and monitoring tasks in logistics and production plants and on production machines and machine tools. New functions, such as motor blocking protection and Quick Stop, not only protect motors but also increase the throughput, productivity and availability of plants.

The powerful, compact Simatic ET 200SP motor starter saves space in the control cabinet and offers versatile control, switching, starting and monitoring functionalities. It reliably protects 1 and 3-phase motors against overload and short circuit when starting. The current values can also be used for energy management functions. Thanks to push-in technology, no tools are required for connecting the motor starters. Parameters are easily assigned with the TIA Portal engineering tool and the starters are connected to a controller without any programming effort. Any faults can be easily found and corrected by a multitude of diagnostic options, such as residual current detection and LED displays.

The Simatic ET 200SP motor starter safely switches off motors in two ways: The Sirius 3SK safety relay, which separates standard and safety engineering, is used for locally limited applications. For system-wide, integrated automation solutions, the safety-oriented F-CPUs of Simatic controllers are used.

New functions include Quick Stop and motor blocking protection. The Quick Stop function stops conveyed goods precisely, which increases throughput and productivity. The motor blocking protection function switches off the plant quickly in the event of a mechanical blockage, such as when a tool gets wedged in the conveyor belt. This protects the motors and increases plant availability.

Source: Siemens Aktiengesellschaft