EBARA Delivers Pumps to Spiber’s Plant in Thailand

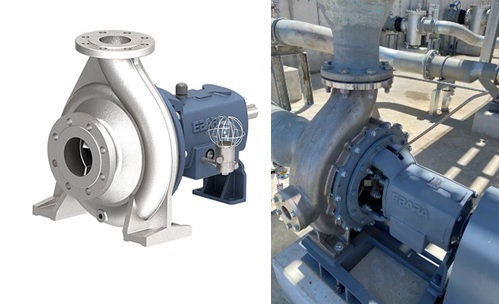

The Model GSO pump delivered and the pump installed in the plant. (Image source: EBARA Corporation)

EBARA has entered into a fundamental business alliance with Spiber, which has successfully established mass production technologies for structural protein materials which have attracted interest as next-generation sustainable core materials. EBARA proposed its pumps for Spiber's plant in Thailand. It was built to mass produce the structural protein materials. The high efficiency of the pumps combined with a consistent support system achieved good evaluations and led to delivery.

The GSO model pumps are used for industrial processes mainly in China and Southeast Asia. The pumps comply with international standards ISO2858 and ISO5199, which are required in the chemical and general industries. EBARA plans to expand sales as global core products with high efficiency. In addition to GSO model pumps, cooling water, fire fighting and water supply pumps have also been supplied.

Through the cooperation with Spiber, EBARA aims to improve the efficiency of production processes to enable the mass production of structural protein materials and improve the use and functionality of structural protein materials as alternative or additive materials of EBARA Group's products. In order to realize the sustainable society declared in the long-term "E-Vision2030", EBARA will deepen cooperation with Spiber and develop innovative materials for industrial machinery products.

The EBARA Group aims to contribute to the achievement of the Sustainable Development Goals (SDGs) by addressing the key issues identified in its long-term vision and executing the medium-term management plan to increase corporate value.

Source: EBARA CORPORATION