Corrosion Resistant Valves Solve Chlorine Injection Problems in Cooling Water System

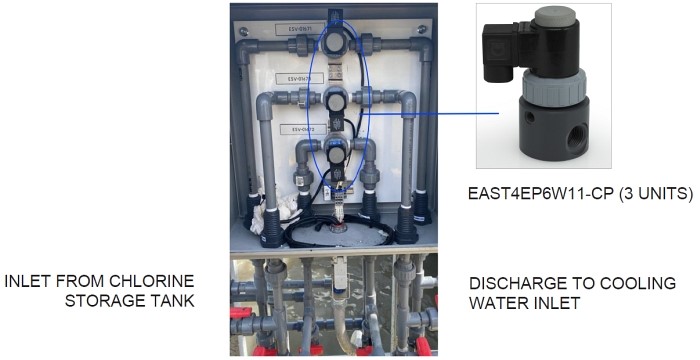

The system requires precise control to maintain accurate concentration for oil refinery fractionators. (Image source: Plast-O-Matic Valves, Inc.)

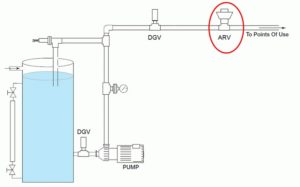

The 15% chlorine is contained in a 5,000-gallon storage tank that is installed on a steel platform built above a cooling water lake inside the barrier of the refinery plant. The same platform holds the pumping system as well as the chlorine injection manifold enclosure that holds the piping and valving responsible for delivering the chlorine.

Precise Dosing is Critical, Five Football Fields Away

The structure sits directly above the inlet piping of the cooling water being pulled from the lake and delivered to the fractionators that are approximately 1500 LF away. A chlorine analyzer positioned at the inlet of the fractionators determines the chlorine content of the water being provided to the fractionators for cooling purposes.

Plast-O-Matic recommended solenoid valve Series EAST in Corzan CPVC for its chemical compatibility, PTFE bellows design to prevent emissions, redundant upper seal, and instant on/off for precise control.

When more chlorine is required, the analyzer sends a signal to the chlorine manifold on the skid to open one, two or all three Plast-O-Matic solenoid valves. This releases chlorine just in front of the cooling water inlet piping that is below the water level of the lake.

Source: Plast-O-Matic Valves, Inc.