Compact SmartSense Pulse System Monitors Temperature and Vibration

Colfax Corporation announced the expansion of its SmartSense intelligent pump monitoring line to include the new SmartSense Pulse.

Colfax Corporation announced the expansion of its SmartSense intelligent pump monitoring line to include the new SmartSense Pulse. (Image: Colfax)

Measuring only 2.4 inches long, 1.6 inches wide and 1.3 inches deep, the Pulse easily fits near the bearing on a pump to gauge temperature and vibration. At-a-glance LEDs on the unit indicate pump performance and provide preventive maintenance alerts when needed.

“Colfax’s SmartSense Pulse is designed to enable a level of monitoring that would otherwise require more staff and diagnostic equipment, which would be expensive and impractical,” said Dan Yin, Ph.D., an electronics engineer with Colfax.

“Temperature and vibration are key indicators of a pump’s operating performance,” he continued. “Excessive levels of either one indicate a need for adjustments, and having a simple, easy-to-use, automated system to constantly monitor pump conditions should enhance operation, reduce downtime and increase energy efficiency.”

The Pulse follows the introduction of Colfax’s initial SmartSense system, whose larger control unit, measuring 22 inches long, 20 inches wide and 10 inches deep, and additional sensors monitor pressure, wear, cavitation and integrity of the pump’s mechanical seal – in addition to temperature and vibration.

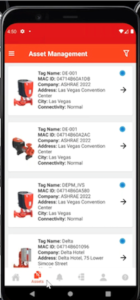

The larger SmartSense system’s control modules can be accessed through the owner’s own data network, the Internet, cell phones or wireless devices and can operate independently using its own customizable algorithm or connected to a group of pumps managed from a central office.

Colfax’s software for the larger SmartSense system also has the ability to alert operators to the need for parts, with accompanying ordering documentation, for regularly scheduled maintenance or to address replacement needs as they arise.

Either system can be installed on new pumps during manufacture or added as a retrofit to existing pumps made by any company. They are applicable for a variety of industries using pumps, such as oil and gas, power generation, mining, chemicals, marine and others.

The SmartSense Pulse will be available for purchase in the first quarter of 2011. The larger SmartSense system is currently available. Both are made in Monroe, North Carolina.

Source: Colfax Corporation