Compact, ‘Armour Plated’ Micropump Is Ideal for Abrasives

Pumping fluids which contain abrasive particles, such as those found in inks and paints can have a detrimental effect on pump performance with erosion being a key factor in reducing pump life.

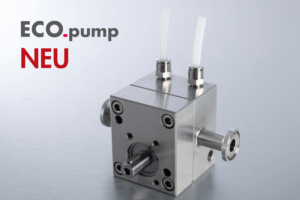

Micropump (Image: Michael Smith Engineers)

With these challenging fluids in mind Michael Smith Engineers has introduced the White Ink pump, the latest addition to the Micropump range.

This modified GJ series Micropump was originally designed for ink jet applications and has the ability to cope with titanium pigmented inks, (those containing 7 micron titanium particles). The pump’s key wetted components have been effectively ‘armour plated’ so they are able to withstand corrosive and abrasive fluids. For solvent based fluids, the White Ink pump features metal gears with ceramic shafts and a pump head of specially hardened stainless steel. For water based fluids, the hardened stainless steel body parts are titanium coated to overcome any possible corrosion issues.

These compact and lightweight, leakfree magnet drive gear pumps are designed to provide flow rates of around 3 lit/min, can generate a maximum differential pressure of 5.6 Bar and can be operated on liquids with viscosities up to 1500 cP at temperatures up to 100ºC.

The external gear design ensures smooth, pulse-free and highly accurate output, so the distribution of process fluids is even and constant, as opposed to the more unpredictable pulsed flows from other types of pump.

Source: Michael Smith Engineers