Cat Pumps for Chick Hatchers

The commercial hatching of chicks is a huge international industry and one company that is an international leader in the design and manufacture of incubation equipment, ventilation heat recovery and energy management systems for hatcheries is Chick Master.

From its manufacturing plants in Bridgwater UK and Medina in Ohio USA Chick Master supplies the world with state of the art systems that produce the highest hatchability and quality.

For chicks to be healthy and stress-free, strict control of the hatchery environment is vital to ensure consistent temperatures and perfect control of humidity throughout the incubation cycle. Because the eggs actually give off a certain amount of moisture, controlling the humidity level in the hatcher is most important. From setting the eggs right through to the emergence of the hatched chicks, temperature and humidity levels need to be strictly controlled to ensure the chicks are fit and healthy. With Chick Master’s hatchers, humidity is provided by a fine mist of warm water which is pumped around the system by high pressure triplex positive displacement plunger pumps manufactured and supplied by Cat Pumps UK Limited.

The hatching process involves eggs being taken from farms and then placed on trays and put into a setter, which is a type of incubator where they remain for around 18 days. The eggs are then transferred into baskets and placed in the hatchers where after about three or four days they hatch out. The number of eggs that can be contained at any one time in a hatchery building depends upon the size and number of the Chick Master hatchery modules used. A two-sector Chick Master Zephyr hatcher will hold more than 60,000 eggs.

The fine mist is essential to the operation of the hatcher and it is the most cost effective way of creating and sustaining the correct levels of humidity. The water used in the system is produced by Reverse Osmosis (RO) in a special plant room and is fed into a high pressure ring main by the triplex plunger pump at a constant pressure of 70 bar and at a temperature of around 65ºC. Solenoid valves are located at intervals along the ring main where humidity is required and these are equipped with nozzles to spray a fine mist into the hatcher units.

The continuous water flow is dependent on the size of the application and can vary between 4.5 litres/min and 12 litres/min. RO water is used because its purity avoids a build up of mineral deposits on the spray heads. However, it has low inherent lubricity so the Cat Pump is ideally suited to the duty as it is designed to pump challenging fluids that can harm other types of pumps.

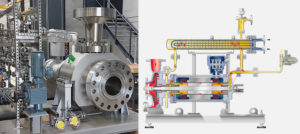

Historically, Chick Master has employed Cat Pumps’ 15 Frame Model 661Stainless Steel belt-driven plunger pumps as these satisfy their requirements for multiple nozzle humidity systems and offer complete flow flexibility and added shock absorption. However, their latest purchase has been for two of the smaller 3 Frame Model 231. “We use the Cat Pump because it is recognised as being a high quality product for industrial applications,” comments Chick Master’s Charles Beecham. “More importantly, the belt-drive packages provide convenient component sourcing and quick system assembly and they can be serviced by our customers anywhere in the world because of the ready availability of spares parts.”

Cat Pumps supplies the pumps with a belt drive motor on a base with pulsation dampeners and captive acceleration tubes, and can operate at a fixed flow or with a VFD to adjust the flow as needed. Where a standby is required the pumps are used in pairs and to meet this requirement non-return valves are primed with water by another small pump to create sufficient inlet pressure.

Cat Pumps offers a complete line of brass and stainless steel high pressure pumps for misting, cooling and humidity control that are suitable for animal and poultry or agricultural applications. These misting pumps can be ultra-compact, direct-drive units suited to portable, low demand misting, cooling and humidity control. For industrial applications, flushed manifold C- and K -316 stainless steel pump models have been designed to handle the unique properties of DI water and larger installation. Custom misting pump units can be sized to handle any number of nozzles or with multiple pumps to come online with changes in demand.

Source: Cat Pumps Ltd.