Case Story: Gear Pumps for Sweet Temptation or as Helpers to the Maître de Chocolatier

It comes in an almost unlimited variety of forms, and its manufacturers know no limits. Combinations are created for sweet-toothed gourmets that range from the regular to the exotic, making chocolate very popular. This popular treat, the sweet drug from the advanced civilisations of Central America, has evolved over the last decade to become a food of luxury and style.

Image: Maag Pump Systems

Image: Maag Pump Systems

The trend towards sweet indulgence in ever-changing new forms is therefore growing. The demand for chocolate with a high cocoa content is currently at a high.

To satisfy consumers tastes, different chocolates are developed depending on the region in which they re sold. Barry Callebaut, the world’s biggest manufacturer of high-quality cocoa and chocolate products – from the cocoa bean to the finest finished product - is currently developing chocolates that melt in the mouth, not the hand, even at high temperatures. Perfection, if you will. Another popular trend at the moment, however, is reduced-calorie chocolate. It is not without good reason that Swiss chocolate is world-famous. Its reputation is down to the Swiss pioneers of chocolate Daniel Peter and Rodolphe Lindt. Over a century ago, Daniel Peter created the first milk chocolate, while Lindt invented the “conching” method that gives chocolate its creaminess.

It’s all about the cocoa butter

To handle all this, there are little helpers in the background that transport the vital ingredient, cocoa butter, that first of all makes the chocolate what it is, and also gives it its incredible flavour and melting qualities. Heated pumps from Maag Pump Systems in a therminox stainless steel design with stainless steel shafts are used to transport the precious cocoa butter.

Aztec luxury

Let’s begin with a brief history of the origins of chocolate: its success story began very early on. Over 3,500 years ago, the Mayans were familiar with the cocoa fruit. It was known as the “fruit of the gods” or the food of the gods (Theobroma cacao). The Aztecs named the cocoa drink, in which the fruit was mixed with cold water xocolatl, which comes from xócoc = "bitter", atl = "water", i.e. "bitter water", or "cocoa water", and from which our modern-day word chocolate stems. This sweet luxury was regarded as an intoxicating aphrodisiac even then, and was reserved for the nobility. Cocoa beans achieved a status that was so high that they were even used as a form of payment.

From the New World to the Old World

With Christopher Columbus’ discovery of America, the wonder drink’ came to Europe. It made its debut at the Spanish court. From there, the drink spread – being sweetened with cane sugar and honey - to rapidly conquer all of the kingdoms of the Old World. Two factors helped chocolate to become a mass product for large swathes of the population in the 18th and 19th centuries: the right technology and new forms of procurement. On the one hand, the right technology allowed the pressing of the cocoa and the subsequent grinding to form cocoa powder to be improved. On the other, the use of cheaper cocoa from the Amazon region, which at the time was under the control of the colonial powers of Portugal and Spain, made it easier to get hold of. The invention of pressing, in which the cocoa butter is separated from the cocoa, along with its grinding, are attributed to the Dutchman Coenraad Johannes van Houten (1801 – 1887).

In small quantities, chocolate can protect against cardiovascular disease

In small quantities, chocolate can protect against cardiovascular disease

(Image: © iStockphoto)

Chocolate can lower blood pressure

According to a German study, chocolate lowers blood pressure and protects against heart attacks and strokes. However, only small quantities of around 7 grams per day are healthy. In the study, researchers at the German Institute of Nutritional Research in Potsdam monitored 19,000 volunteers over a period of eight years. The result: people who ate on average seven grams of cocoa-containing chocolate per day had an almost 40 per cent lower risk of cardiovascular disease, according to the scientists. The group’s risk of a stroke fell by half, while the risk of a heart attack was reduced by almost 30 per cent. “Chocolate is known for its blood pressure-lowering effects,” says study author Brian Buijsse, and particularly recommends chocolate with a high cocoa content. This is because the health-giving properties lie in the cocoa: it contains the substance flavanol, which has a favourable effect on blood pressure. Generally speaking, the ingredients of chocolate have a stimulatory and mood-lifting effect. So it is no wonder that the GIs during the Second World War received a daily ration of chocolate. Dark chocolate with a high cocoa content also has anti-oxidative properties, helping it to protect the vessels of our heart. As always, everything in moderation.

The basics of chocolate production

Three basic types: cocoa paste, cocoa butter, sugar and milk powder are the four basic ingredients that go into making chocolate. By mixing these ingredients according to certain basic recipes, it is possible to create three basic types of chocolate that form the starting point for all later chocolate products:

- Dark chocolate (cocoa paste + cocoa butter + sugar + vanilla)

- Milk chocolate (cocoa paste + cocoa butter + sugar + milk powder + vanilla)

- White chocolate (cocoa paste + sugar + milk powder + vanilla)

Technology determines the taste

If we take a look at modern-day chocolate manufacturing practices, it s clear that industrial production is a very technical affair. If the cocoa paste is to be transformed into chocolate, it has sugar, possibly also cocoa butter, and milk products added to it, depending on the final product. To create chocolate paste, cocoa butter is used not only as part of the cocoa paste, but also as a pure fat. Cocoa butter is obtained by pressing prepared cocoa paste.

Grinding, mixing, rolling

To begin with, the cocoa beans are coarsely ground in a crusher. The shells of the ‘cocoa nib’ are suctioned off using strong air currents for further use in other industries. The cocoa nibs, which are still coarse, are then ground in special mills to create a fine “cocoa paste”. The heat generated by the pressure and friction allows the cocoa butter (approx. 50%) contained in the beans to melt. The now liquid cocoa paste is very dark in colour, it has a characteristic, strong aroma and flavour and gradually thickens as it cools. At a particle size of around 100 mµ, it forms the basis for chocolate production. A delicate melt is only achieved at a particle size of less than 25 mµ (thousandths of a millimetre). If the chocolate is too coarse, it has a rough, sandy character. If the particles are too small, the chocolate sticks to the teeth.

In the next step, the cocoa paste goes into the ‘mixer’, or ‘mélangeur’, where it is blended with the other three basic chocolate ingredients of cocoa butter, sugar and milk powder along with the closely-guarded secret ingredients in the relevant recipe, all added in precisely the right quantities, and then kneaded intensively for 30 minutes.

The fat content determines the flow characteristics, and the mixture must be of a very specific consistency when it leaves the mixer in order to achieve the best rolling results in the next stage of the processing chain. In the ‘raffineur’, the cocoa paste is rolled out in a two-stage process to create a wafer-thin layer: it first passes through a twin roller and then through a five-roller mechanism (comprising five cooled steel rollers that prevent the paste from liquefying). As a result of all this rolling, the coarse chocolate paste is transformed in the heat and pressure into a much finer mixture whose individual components are no longer distinguishable to the human tongue (15 to 20 mµ).

The “cocoa cake”, as it is known, is produced almost as a by-product of the rolling process. This cocoa cake is ground and sieved to produce cocoa powder. The cocoa butter which is also obtained during the rolling process is a very valuable fat with a strong aroma.

Conching – the way to refine chocolate

In its original state, the cocoa paste is still very bitter and sharp, since the individual ingredients have not yet blended together perfectly. This is why the chocolate is “conched”, or refined. In the “conching” process, as it is known, the paste is warmed and moved for hours at a time. Unwanted aromas are made to disappear and the cocoa butter surrounds the tiny particles of chocolate. The effect is that the chocolate no longer tastes as bitter, it becomes creamy and it melts beautifully on the tongue. This inspired method was developed by Rodolphe Lindt as far back as 1879, five years after Daniel Peter invented milk chocolate.

It’s all about the melt

Some of the cocoa paste is fed through large hydraulic presses, which removes most of the cocoa butter. Cocoa butter is a fine and valuable fat with a marked aroma. Filtered and purified, it looks similar to regular butter, but is significantly harder. Together with the cocoa paste, it later gives the chocolate a fine structure, beautiful gloss and a delicate, pleasant melting quality.

The magic word: cocoa butter

Cocoa butter is an important raw material for creating chocolate. It is what makes chocolate chocolate, and gives it its incredible flavour and melting properties. Cocoa butter is one of the most expensive vegetable fats there is. The cosmetic and pharmaceutical industry also uses cocoa butter for everything from beauty products to suppositories. Cocoa butter is what makes chocolate what it is: sweet seduction.

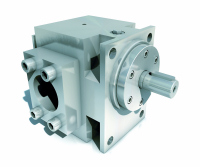

Food technology of the highest standard: heated pumps series therminox from Maag Pump Systems in the TX stainless steel design with stainless steel shafts (Image: Maag Pump Systems)

Food technology of the highest standard: heated pumps series therminox from Maag Pump Systems in the TX stainless steel design with stainless steel shafts (Image: Maag Pump Systems)

Swiss-made conveyor technology

To convey the paste, which is as expensive as it is demanding, gear pumps from Maag Pump Systems are used. The special requirements of the application are addressed by the heated version of a stainless steel design that uses stainless steel shafts. The gear wheel shafts in this case are made from hardenable 1.4112 stainless steel and offer a sufficient degree of durability. A heated design is also useful for ensuring that the specified process temperature can be constantly maintained and that no quality differences can occur. When the paste is transported, a constant temperature avoids the phenomenon of caramelisation. Any caramelisation of the sugar in the paste could lead to wear during transport, especially in the bearings, which is not permitted in the food industry.

Maag chose a bearing made from sintered silicon carbide, since this ceramic composite material is not only highly resistant to abrasion, but its heat conduction properties also help to prevent the material from degrading. As a food-compatible material with excellent emergency running properties, it is also perfectly suitable for cleaning cycles with runny media. Silicon carbide is also virtually unaffected by temperature changes. This means that the hole in the bearing needs to be sufficiently large right from the start to ensure that the bearing doesn t shrink onto the shaft when it expands. This is ensured by using application-specific classes of play.

Viscosity shapes the process

In the bearing, the cocoa paste becomes more liquid due to the friction and resulting heat. Generally speaking, this effect is not serious for runny pastes. However, the higher the viscosity, the easier it is to build up a more stable film of lubrication. This change in viscosity can be counteracted using design modifications such as special lubricating grooves, bearing geometries or flow crossovers. Specific clearance classifications, both for the shafts and the bearings, help to satisfy the requirements. These allow "new" paste to be constantly fed to the rotating parts, keeping them constantly lubricated. Degradation of older, stagnant material and therefore the development of the dreaded wear are avoided. For the seal, a simple sliding ring seal with a silicon sliding ring is used on Maag pumps that offers simple handling and reliable operation.

Summary

The efficient coordination of all the pump components with each other is achieved through an in-depth understanding of the technology involved; thereby allowing the economical use of gear pumps in the food industry – and this also goes of course for the master chocolatier.

| Info box 1: Background information on EU law

As part of the amendment of laws within the European Union, the legal situation pertaining to chocolate production was also integrated. In March 2000, the European Committee issued a decree “on cocoa and chocolate products for human food”. The most important change involves the use of other vegetable fats, which was already permitted in several European countries. Now, German manufacturers are also allowed to replace up to 5% of the cocoa butter with other vegetable fats that are equivalent to cocoa butter (e.g. palm oil or mango core). The label on the chocolate product must however provide precise information on the ingredients: if cocoa butter-equivalent fats have been used, this must be clearly identified on the front and back of the packaging. Not only are other vegetable fats cheaper than the comparatively expensive cocoa butter, but they also have a positive effect on a) the shelf life and b) the melting point of chocolate. a) Cocoa paste, cocoa butter and sugar, as well as in some cases milk powder and condensed milk, age only slowly. This means that chocolate is a food and luxury item with a long life. Its ideal storage conditions are between 10°C and 18°C, protected from light, moisture and strong odours. If stored for too long, the aroma and appearance do suffer, but such chocolate is not harmful to health. The completely harmless white bloom that sometimes appears on chocolate is caused by the chocolate being stored in too warm an environment and is the result of the separation of cocoa butter. Depending on its composition, chocolate has a shelf life of up to 12 months, with dark chocolate even keeping for up to 15 months. Chocolates with fillings “age” more quickly, of course. Alcoholic fillings evaporate and chocolates containing fresh cream fillings need to be eaten within a few days. b) Manufacturing chocolate that doesn’t melt on hot summer days isn’t a problem from a technical perspective. The only problem is that this type of chocolate would need to be chewed, as it wouldn t melt in the mouth either - somewhat ruining the actual enjoyment of the chocolate. Critics of this new EU decree state that the use of cocoa butter-equivalent fats reduces the quality of chocolate products. The reduced use of cocoa beans would also affect the price of cocoa, and consequently the wages of the cocoa growers. |

| Info box 2: Did you know?

With an annual per capita consumption of almost 12 kilograms of chocolate, the Swiss are the world leaders. Germany comes second, with an average consumption of 11.4 kilograms, while the Japanese, with an annual consumption per capita of just 2.2 kilograms, represent an industrial nation that barely touches the stuff. |

Author:

Bodo Schulte-Ellerbrock

Product Manager Industrial, Maag Pump Systems AG

Source: Maag Pump Systems AG