Case Story: Aromas and Scents – The Seducers of the Senses

Flavour through constant processes – gear pumps from Maag for the aroma industry

Image: Maag Pump Systems

Image: Maag Pump Systems

No fewer than 75 percent of our emotions are influenced by the perception of aromas and scents. And frequently, before we even know it, our clever sensory system tells us what to do. No less extraordinary is the world of aromas. “E100, E124, E132, E901” … - everyone is familiar with these cryptic codes on food packaging. The countless "E s" that accompany us along our everyday lives in everything we eat or see. Sometimes they re used to make things last longer. Sometimes they enhance a flavour. The aroma kitchens of leading manufacturers are where the taste trends of tomorrow are born.

Frequently, concentrated solutions of aromas or flavourings are added to end products to match the expectations of the intended consumer group. The decision regarding what we like and what we don’t is one we make in a few fractions of a second. Our inner jury is merciless and has exacting subjective ideas of what’s good and what’s not. As a result, it is supremely important for the industry to make it easy for consumers to choose. Added to this is the fact that the decision regarding what food, what drink or what scent is chosen depends also on group-specific emotional and cultural factors. There are different, country-specific formulas for what most people would assume to be global products, such as Nescafé, Coca-Cola or Pepsi, which take account of different preferences. These products are consistently regionalised in order to appeal to local tastes. Consequently, even coffee tastes very different depending on whether it s ordered in Sweden, France or Italy.

Aromas ensure a constant and intense taste experience

If the product s own aroma is not enough, natural or nature-mimicking aromas are added as a food additive. This is usually down to cost reasons. After all, it is not always the right season for raspberries, but people like to enjoy the taste of raspberries all year round. The price of aromas varies greatly. For natural aromas, dependence on the producer becomes a real burden, since significant quality differences and huge fluctuations in supply volumes can occur due to climatic or political influences. On the other hand, nature-mimicking aromas can be used to create numerous very appealing, consistent odour and flavour qualities that are no different in terms of acceptance from natural substances, and in fact are often superior to them.

Scents and aromas as secret seducers

Today, aromas and additives very often decide the success or failure of a new product. For this reason, considerable efforts are made in the industry’s scent and aroma laboratories to create a unique aroma for this product. It’s all about authenticity and uniqueness. Olfactory perception (from the Latin olfacere, meaning ‘to smell’), or the sense of smell, olfactory sense or perception of smell, are all terms given to the perception of aromas. The sense of smell is one of the longest-established senses in humans. Two sensory systems are involved: the olfactory and the nasal-trigeminal system. Smell and taste interact and influence each other. Even during eating, the nose plays an important role. As scientists have discovered, the taste perceived is influenced greatly by a dish’s aroma.

Scents determine whether we feel good or not. In this case, natural aromas are used too. But to not only ensure the quantity, but also the intensity and consistent quality, these natural aromas are imitated with synthetic products. Aromas are used in a great number of different ways. As a result, aromas are added to many drinks such as tea, coffee, fruit juice and even more recently to water, but also to fresh products such as ice cream, desserts, cheese and yoghurt. The classic aromas are unassailably vanilla, followed by lemon, strawberry and chocolate.

How scents and aromas work

The cells in the nose send a signal to the brain. The nose has the ability to perceive a huge range of different scents and also distinguish between them. Humans have around 30 million olfactory cells in the olfactory mucosa located in the upper part of the nose. Humans also have 350 olfactory sensors all over their body too, however. This is why people don’t just smell with their nose, but also with their skin. The aroma centre in the brain receives the information, which is compared with various templates’ to define and discern the scent: good = I like it, or not good = I don’t like it. This creates a massive archive that we can access whenever we want. In principle, humans are able to distinguish around 10,000 aromas. Untrained noses, however, are only able to actually recognise and name around 50 per cent of the aromas. Even after many years, however, we remember very clearly what the burnt milk smelt like in nursery. We remember an intense smell virtually all our lives. The sense of smell is the most complex chemical sense. Try expressing the impressions smells give you in actual words!

Sensory processing

It all takes place in the limbic system, where we store our memories and emotions. This system also controls our behaviour and in the past was essential for survival, helping us to quickly recognise danger and act accordingly. In those days, aromas and scents had the function of an early-warning system. Even today, although most of these instincts have become redundant, we still associate the smell of a sulphur with a burning match, fire and therefore danger. Certain smells are classified by our limbic system as “bad”, “unpleasant” or “dangerous”. This enables us to make decisions extremely quickly.

Stimulus and receptors

Taste receptors perceive six different tastes: sweet, salty, bitter, sour, umami, which is derived from glutamate, and the taste of fat. Bitter or sour tastes often indicate poisonous or decayed food. Even our Stone Age ancestors had these types of receptors on their tongues. Being able to distinguish bitter tastes could in some circumstances save your life, because a lot of bitter-tasting fruits contain high quantities of hydrocyanic acid. The taste qualities sweet and salty indicate nutritious foods. For these reasons, the taste organs are always found in the parts of the body that are used in the intake of food, such as the tongue or the gums.

Change and trends

Even our own preferences changes over the course of our lives: when we are young, we often prefer sweet tastes, but later we also like salty ones. Only after a lot of experience and once we are older do we also try sour or even bitter tastes such as coffee, Parmesan, blue cheese or dark chocolate. As we age, the bitter taste stimulates our appetites. These age-specific inclinations are very important for new product designs in the aroma industry.

A clear vote: the decision to buy what smells or tastes good

Scent and aroma are important selling points for consumers. For 45 percent of consumers, taste is the most important decision-making criterion when buying food and drink, according to a study by the market research firm AC Nielsen. With perfume, the percentage rise is significantly higher, at just under 80 percent for a positive scent. Scents generate feelings and desires that our intellect is unable to control. Scents help us to find our way, communicate and even find our mates or partners. Or to put it more simply, if "the chemistry" is right between two partners then this largely down to each individual liking the other s body scent.

Interpreting signals

The smell of disinfectant is associated with pain and fear. For this reason, many doctors or hospitals use the scent of lavender, which has a calming effect. Vanilla, on the other hand, give us a feeling of safety. Even in the automotive industry, smell analysts evaluate whether a new car smells nice. The manufacturer of room scents are also very busy, and earn good rewards on their balance sheets. Scents give us a feeling and a mood – and if we feel happy, then we’re also willing to spend more money.

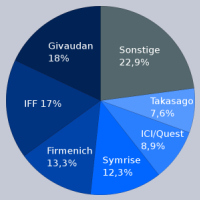

World market share of aromas and fragrances (Image: Maag Pump Systems)

World market share of aromas and fragrances (Image: Maag Pump Systems)

The boom of the aroma industry

Scent and flavouring experts such as Symrise in Minden (Germany) make use of these mechanisms. The Holminden company supplies to manufacturers of perfumes, foods, cosmetics and hygiene products in around 160 countries. The company’s portfolio comprises more than 30,000 tailor-made products alone. Even a conventional strawberry aroma turns out to be a complex affair. Scientists have found that the aroma of a single strawberry is made up of more than 300 different chemical compounds. Symrise’s recipe for success is that 90% of its products satisfy human basic needs – which is why they are in demand even during times of crisis. Each year, 170,000 tonnes of aromas are added to food in the EU alone. Over 500 companies share a global annual turnover of just under Euro 15 billion (2010 figures). According to estimates by the investment firm Kepler Capital, the market leader Givaudan (CH) holds a market share of 25 percent, while Symrise from Germany ranks 4th in the world with a share of around 12 percent. In second and third places are the heavyweights such as Firmenich (CH) and the US firm IFF (International Flavors & Fragrances).

Supporting healthy nutrition

The industry is pinning great hopes on the growing popularity of healthier nutrition. This is because, along with fat and sugar, food producers are also banning important flavourings from their products. Additives from aroma manufacturers ensure that healthy products retain the familiar flavour for consumers, even though they are low-fat or low-calorie versions. With other foods, unpleasant side effects can be reduced. The very healthy omega 3 fatty acid has the unpleasant taste of cod liver oil. It may be healthy, but it tastes vile. And because none of us really wants this flavour in their breakfast yoghurt, the relevant molecules are encapsulated, allowing them to slide past the consumer s taste sensors undetected.

Applications in the scent and aroma industry

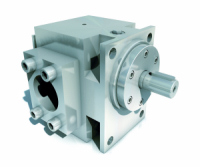

When it comes to manufacturing aromas, it s all about the highly accurate dispensing of low-viscosity scent and aroma components using gear pumps from Maag Pump Systems. These constantly and precisely transport the scents with a pressure differential of 1 bar directly from a reactor. Two factors are crucial: the mixture of the individual components and the right ratio. The exact quantities of the individual components that are blended in the mixing process determine the quality of the product. They are regarded as key control variables. For this reason, highly accurate and low-pulsation stainless steel gear pumps from the cinox series, or the heated version therminox, are used for this process.

Process reliability for aroma manufacturing: high-precision and low-pulsation stainless steel gear pumps in the cinox from Maag (Image: Maag Pump Systems)

Process reliability for aroma manufacturing: high-precision and low-pulsation stainless steel gear pumps in the cinox from Maag (Image: Maag Pump Systems)

Flawless: stainless steel shafts and sliding bearings

The stainless steel shafts and bearings made from synthetic carbon guarantee superlative resistance. Often, sliding bearings made from carbon are used for liquid, aqueous and low-viscosity media. Along with its special properties and ability to offer excellent resistance against acids and other corrosive media, carbon also offers excellent emergency running properties. This means that it can be safely used with low-viscosity media and used for all kinds of cleaning cycles.

Remembering thermal expansion

Generally speaking, the components’ different thermal expansion parameters need to be taken into account. Carbon exhibits virtually no expansion when heated. For this reason, the hole in the bearing needs to be sufficiently large right from the start to ensure that the bearing doesn t shrink onto the shaft when it expands. This is safeguarded by Maag with play classes that are selected on an application-specific basis.

Increasing the level of efficiency

For very runny, watery media, it is very difficult to achieve an acceptable volumetric level of efficiency, since the degree of efficiency of the gear pump depends greatly on the axial play between the bearings and the shafts. To nevertheless boost efficiency, the play is kept very small (single-digit µm for small pumps). This depends heavily on the different temperature coefficients of the materials used to make the housing, shafts and bearing.

The influence of temperature on viscosities

A rising temperature also reduces the viscosity of the transport medium. This has a negative effect on the lubricant film on the bearings, for example. What’s more, the temperature in the bearing needs to be kept as low as possible in order to avoid the effect of a reduction in the viscosity of the transport medium: a negative effect on the lubricant film can result. These effects require the external temperature in the Maag gear pump to remain limited to a minimum. It helps in this case to control the temperature of the housing.

The pressure differentials achievable in a gear pump are primarily dependent on the thickness of the lubricant film in the sliding bearings. This in turn is dependent on the viscosity of the medium and the speed of the pump. In order to take full account of the viscosity, the gear pump s pumping principle needs to be brought into the equation. Inside the pump, this principle can cause material losses which can lead to heating of the medium and therefore to an unwanted reduction in viscosity. These leakage losses influence the level of a gear pump s efficiency. The aim of every design is to achieve the highest degree of efficiency possible. For chemical applications with viscosities of around 1 mPa/s (water) and poorly lubricating media, it is very difficult to build up a suitable lubricating film. Subquadratic pump designs, in which the gear width is reduced while the axle distance and bearing width remain the same, provide a solution or improvement for this. With these designs, Maag pumps can achieve differential pressures of up to 15 bar.

Cleanliness, reliability and process safety

Since the media in question are neither dangerous nor explosive on contact with the atmosphere, a good and low-maintenance, simple sliding ring seal is chosen that features simple handling and reliable operation. This ensures that the customer benefits from long maintenance intervals and process reliability. In each production facility, there are key components that would stop production were they to fail. For this reason, priority was given to high-quality and reliable components when designing the process. Even one unexpected halt to production could have severe financial consequences. Cleanliness, reliability and process safety are therefore the most important criteria when handling and processing foods.

Author:

Bodo Schulte-Ellerbrock

Product Manager Industrial, Maag Pump Systems AG

Info box: Classifications of aromas

On 31st December 2008, EU Directive 1334/2008 on the definition and use of aromas was published in the European Law Gazette. |

Source: Maag Pump Systems AG