Blackmer System One Centrifugal Pumps for the Storage Terminal Industry

Blackmer announces that its System One centrifugal pumps are designed for high-volume, severe-duty applications making them ideal for critical applications in the terminal industry, including unloading barges, ships, railcars and tank trucks, and transferring liquids from terminal tanks to loading platforms.

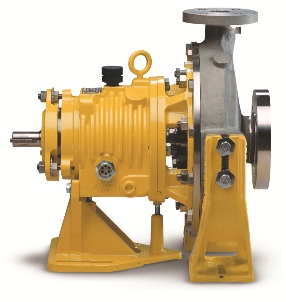

Blackmer System One Model LD17 (Image: Blackmer)

Designed around the seal where 90% of pump failures occur, the System One has a stiffer heavy-duty shaft and larger bearings resulting in the widest operational window off the Best Efficiency Point (BEP) than any standard process pump. This means terminal operators can expect the System One pump to improve mean time between failures to reduce maintenance costs.

The System One is available on three frame variations, with multiple size configurations for nearly any terminal transfer application. Each frame type offers the lowest L3/D4 stiffness ratio of any competitive size pump. The Frame S is a heavy-duty alternative to standard small frame pumps, delivering capacities to 450 gpm (102 m³/hr) while meeting ASME/ANSI dimensional specifications. The Frame A/LD17 has the most stable shaft for its size in the industry that dramatically reduces bearing, sealing device and shaft failures. It reaches capacities of 1,400 gpm (320 m³/hr) and is available in IPP metric construction. The Frame M is the only ASME/ANSI B73.1 pump of its size that offers centerline mount for high temperature applications. The Frame M pump also includes an optional left/right side discharge and vertical mount configuration.

Source: Blackmer