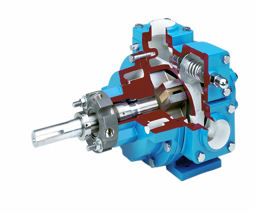

Blackmer NP Series Sliding Vane Pumps Offer Reliable Product Transfer in Asphalt-Handling Applications

Blackmer, a global leader in positive displacement pumps and reciprocating-gas compressor technologies, has announced that its NP Series Sliding Vane Pumps have been designed to provide efficient transfer when handling asphalt or bitumen.

Blackmer

NP Series pumps are ideal for all of the different transfers of raw products from storage into the refinery, and from process to process within asphalt operations.

The NP Series pumps can meet the needs of these demanding asphalt-handling applications because they have been designed for the handling of a wide variety of liquids at varying temperatures, pressures and viscosities. This allows the NP pumps to offer maximum versatility while sustaining a high-level of performance and trouble-free operation.

NP Series pumps are available in five sizes, with port sizes from 1.5- to 4-inch. They feature flow rates from 5 to 500 gpm (19 to 1,893 lpm) at operating temperatures up to 500°F (260°C), with an optional jacketed pump head for high-temperature operating atmospheres. They can handle viscosities ranging from 30 to 20,000 ssu (4,250 cP) at differential pressures up to 150 psi (10.3 bar) with standard construction, while an adjustable relief valve protects against excessive operating pressures. With optional materials, maximum viscosities can go to 100,000 ssu (22,000 cP) and differential pressures up to 200 PSI (13.8 bar).

All NP pump models feature Blackmer’s revolutionary sliding-vane operating principles, which guarantee consistent volumetric performance, even after significant in-service time. This eliminates the efficiency-robbing “slip” that shortens lobe and gear pump life, and improves production yields by stripping lines of residual product. NP pumps also offer excellent self-priming and dry-run capabilities.

Source: Blackmer