Baker Hughes Installs World’s First Ultra-Temperature SAGD Production Systems

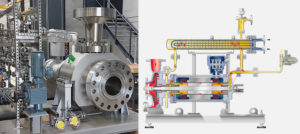

Baker Hughes has installed the world’s first ultra-temperature electrical submersible pumping (ESP) systems in steam assisted gravity drainage (SAGD) wells in the Canadian oil sands.

Nine Centrilift XP ESP production systems, which can operate at fluid temperatures up to 250°C (482°F), have been installed since April 15, 2010.

Calgary-based Cenovus Energy, currently field testing the system at its Christina Lake, Alberta, thermal project, is among the first to deploy the new technology. “We expect the more robust system to increase run life and minimize operational expenditures,” says Jason Abbate, a production engineer with Cenovus. “Because the ESP system is operated at higher temperatures than conventional systems, we can also expect higher oil production rates.” SAGD production specialists expect an increase in production with a larger steam chamber and less viscous oil at higher steaming temperatures.

The ultra-temperature ESP system design is the result of several years of intensive research and development in specialized testing facilities at Baker Hughes’ ESP product center in Claremore, Oklahoma, USA. The one-of-a-kind testing facilities allow Baker Hughes’ research and development engineers not only to design and test ESP equipment at temperatures up to 300°C (572°F), but also to simulate the horizontal orientation and temperature cycling characteristics of SAGD wells. The tests conducted in the dedicated high-temperature test loop ensure that the highest levels of reliability are designed into the ultra-temperature ESP systems.

Baker Hughes instituted stringent manufacturing, factory acceptance testing, assembly and field service processes to ensure maximum reliability for these harsh applications. The SAGD ultra-temperature systems also have dedicated application engineering and technical support teams for this emerging market.

“Baker Hughes invested in the industry’s only testing facilities capable of simulating these intense temperatures because we are committed to expanding the technology boundaries for SAGD production systems,” says Mike Davis, president of Baker Hughes operations in Canada. “We anticipate this new robust system design will make a significant difference in infrastructure costs for SAGD wells that require these high temperatures.”

Source: Baker Hughes, a GE comany LLC