Avoiding Emission Problems

There are health and environmental risks associated with the handling of solvents. The gas which is released into the air is toxic, and it is also explosive. Lutz has developed a safe, efficient solution which avoids emission problems and enhances health and environment management in the chemical industry.

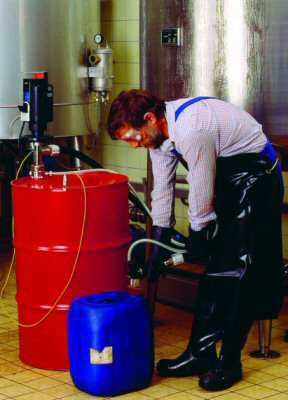

(Photo: Lutz-Pumpen).

A variety of solvents are kept in a special storage area in stainless steel canisters. Toxic, flammable gas is released when the solvents are opened or when the solvents are transferred. Personnel have to wear breathing equipment and take elaborate safety precautions when they are handling solvents.

What the customer really needs is a safe method to transferring solvents from 200 liter drums into smaller canisters. The pump must be attached in a way that reduces the release of gas to an absolute minimum, and there should be no need to wear breathing equipment in the storage area.

Lutz has come up with a solution using a pump made of stainless steel which completely drains the canisters. The pump has an integrated backflow stop. Users can drain containers leaving virtually no residue, and there is no risk of mixing solvents. A Lutz emission control drum adapter is used to attach the pumps. The adapter also provides the necessary pressure equalization without allowing dangerous gas to escape. An equipotential bonding cable as well as conductive tubing and fittings are used for grounding. The system also has nozzles with automatic shut-off and solvent-resistant seals to provide complete safety protection. Automatic nozzles are needed because personnel are unable to see how much solvent is left in the canisters.

This solution has a number of benefits to the user. Because the pump completely drains the canisters and since the pump is easy to attach to the motor, only one pump is required per storage room. The motor features double insulation and explosion protection, and it is Atex 100a approved.

Workers can quickly attach or remove the motor. There is no need for cumbersome breathing and exhaust equipment in the storage areas. Very little residue is left in the drums, making them easy to clean and refill. Complete drainage and segregation of media reduce the amount of special waste that requires expensive disposal.

Source: Lutz Pumpen GmbH