Amarinth Wants to Become IECEx-Compliant Manufacturer of Mechanically Sealed Pumps

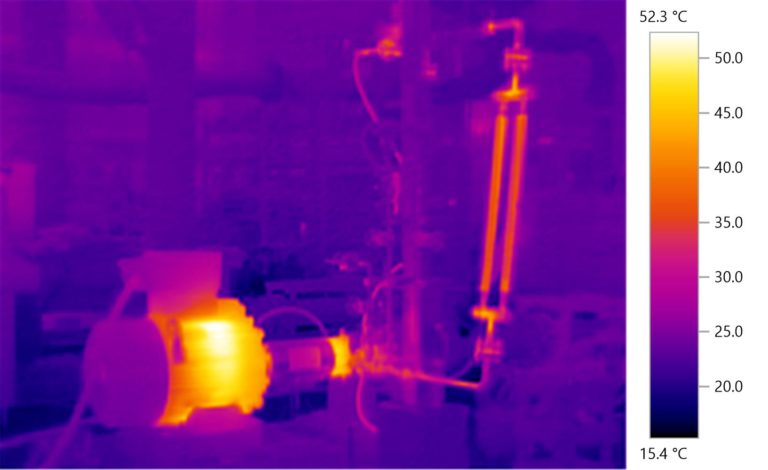

A thermal image of an Amarinth pump in operation undergoing IECEx certification. (Image source: Amarinth Ltd.)

IECEx is the IEC System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres. It uses quality assessment specifications that are based on International Standards prepared by the International Electrotechnical Commission (IEC). The IEC has been active in driving plant operators and end-users to adopt IECEx across all electrical and non-electrical equipment and therefore package providers and contractors are now being asked to provide IECEx certified non-electrical equipment, which given that most non-electrical equipment manufacturers have not even started the process to become IECEx certified can prove difficult to source. Unlike ATEX, all equipment that is IECEx certified must be independently tested and certified to carry the IECEx certificate, and there is only one certificate with restrictions on use stated in the notes and no differentiation by explosion risk zones.

Amarinth was being approached more regularly by customers asking for non-electrical equipment to be IECEx certified instead of, or in addition to, the usual ATEX certification. The company therefore decided it was time to embark on gaining IECEx certification and in so doing intends to be the world’s first IECEx compliant API 610 / ISO 5199 mechanically sealed pump manufacturer.

The IECEx certification process is comprehensive. In addition to ensuring the requirements of IECEx are covered by any existing quality system, such as ISO 9001, it includes achieving compliance with several other ISO standards. Assessment of overall compliance with IECEx and of the product technical file is then undertaken by an independent notified body before final certification of the company and its products to the IECEx standard.

Amarinth has recently completed its certification to ISO 80079/34 as part of its IECEx strategic project taking it one step closer to IECEx compliance. ISO 80079/34 is the quality management system specific to IECEx that specifies requirements and information for establishing and maintaining a quality management system to manufacture products for use in an explosive atmosphere in accordance with the certificates. This is in addition to Amarinth’s existing 9001 certification.

There are now two remaining standards that Amarinth is progressing regarding the products, ISO 80079/36 and ISO 80079/37, which cover the requirements for the design and construction of non-electrical equipment intended for use in explosive atmospheres. Once these are completed, approved and certified, which is expected to be by the end of this year, Amarinth will have completed all the necessary steps to become the world’s first IECEx compliant mechanically sealed pump manufacturer.

Oliver Brigginshaw, Managing Director of Amarinth, commented: “Despite the many difficulties caused by the global Covid-19 pandemic, we have continued with our progress to become IECEx compliant. We are now confident of achieving this very soon, which will give our customers the ability to purchase fully IECEx compliant API 610 and ISO 5199 pumps.”

Source: Amarinth Ltd.