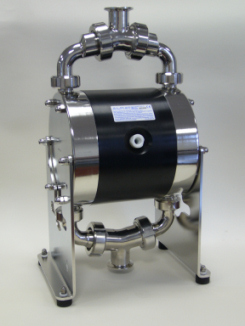

Almatec BIOCOR Series Feature Unique Diaphragms, Ball Valves and Air Control System

Almatec has designed its BIOCOR Series of Aseptic Air-Operated Diaphragm Pumps to meet the strict standards, regulations and operational requirements that govern the manufacture of food products.

Almatec BIOCOR Series

In fact, Almatec’s BIOCOR pumps have earned certification from the European Hygienic Engineering & Design Group (EHEDG), FDA conform and 3A approval.

Playing a role in the ability to meet these high standards are the BIOCOR’s standard-setting diaphragms, ball valves and air control system. Almatec’s diaphragms are state-of-the-art because they are smooth and not interrupted by any seals. Due to their integrated metal core, they also do not require the use of a diaphragm disc, which can be prone to leaks. Almatec diaphragms have been designed from the “PTFE” point of view, with large diameters and short strokes within a low flexural load. The BIOCOR diaphragms are available in EPDM (FDA) or PTFE-EPDM composite materials of construction.

BIOCOR’s ball valves are insensitive against solids and have a metal core for a better suction lift. In addition, ball-lifting magnets can be used to produce complete draining. BIOCOR pumps are equipped with Almatec’s patented PERSWING P air control system. This metal-free, pneumatically piloted control system ensures accurate reversal of the main piston and is characterized by low noise levels. Only two moving parts ensure that there is absolutely no dead center in the PERSWING P control system. It does not require maintenance, operates without any lubrication whatsoever and is made up of no more than four different parts.

Source: Almatec Maschinenbau GmbH