Air-Operated Double Diaphragm Pumps Provide High Level of Sanitation in Wine-Making

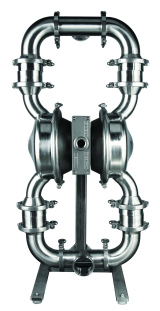

The Saniflo Hygienic Series (HS) Air-Operated Double Diaphragm Pumps have been specifically designed to meet the strict guidelines that are being established for sanitary process applications in wine production.

Wilden, USA

The focus is to eliminate unwanted microbiological activity and contamination that could result in entire batch loses or may adversely affect the quality of the final wine produced. This new technology with higher surface polishes (32 ra), no crevices, and no dead legs eliminates possible points that would generate unwanted microbial activity. This provides winemakers with new options regarding the use of SO2 and other preserving ingredients, as well as the ultra-filtration needs.

Typical applications include general transfer, pump over processes, blending, barrel feeding/topping, filter feed, lees handling and filler feed. Besides the high cleanability introduced with this series, Saniflo Hygienic Series pumps also feature the standard benefits of self priming, dry running, dead head capability, low shear transfer and portability already well established with Wilden double diaphragm pumps in this industry.

In addition to being designed for the highest hygienic requirements, Saniflo Hygienic Series pumps are certified independently as such. They utilize standard FDA compliant materials, and when properly equipped they carry the 3A Symbol based on standard 44-03. This standard validates sound hygienic design and EHEDG Doc. 2 and 8, which certifies cleanability.

The pumps also come equipped with the patent-pending Pro-Flo X air-distribution system (ADS) and Efficiency Management Systems (EMS), which allows the user to control the pump’s flow rate and efficiency with the turn of a dial. Depending on the application, this produces a significant reduction in air usage.

Source: Wilden