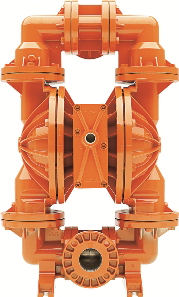

Air-Operated Double-Diaphragm Pumps for Paint & Coatings Manufacturing Applications

Wilden announced that it now offers bolted “drop in” style replacement pumps for the majority of applications found in Paint & Coatings manufacturing facilities.

Wilden

The term “drop in” refers to a pump’s ability to be installed in an existing pump footprint without the need to disturb piping.

Wilden’s Air-Operated Double-Diaphragm drop-in pumps are currently available in the Advanced Series Metal 25mm (1”) bolted stainless steel and aluminum, 38mm 1-1/2”) bolted stainless steel, and 76mm (3”) bolted stainless steel and aluminum models. Wilden drop-in style pumps have larger flow paths than the pump they are replacing, resulting in increased flow rates and decreased energy consumption over competing Air-Operated Double-Diaphragm pump technology.

Wilden’s Advanced bolted pumps include a variety of elastomer options, as well as the Pro-Flo X air distribution system which allows the pump user to control the flow rate and maximize efficiency to reduce processing costs. Other product options such as full-stroke PTFE diaphragms and DIN flanges are available for specific application requirements.

Source: Wilden