ADT Introduces Diamond Wear Surfaces Optimized for Dry Running

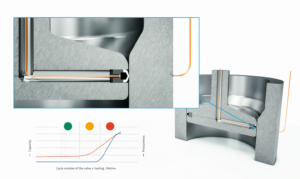

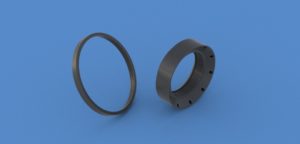

Advanced Diamond Technologies (ADT) announces UNCD T30TM, a new addition to its growing UNCD family of diamond materials. UNCD T30 is specifically optimized to withstand fluid loss or dry running in mechanical seals for fluid pumps.

Fluid loss is one of the largest causes of premature failure in rotating equipment resulting in equipment damage, lost production, and environmental contamination.

UNCD T30, when applied to a silicon carbide mechanical seal face, can be run against a variety of hard counterface materials (e.g., silicon carbide, graphitized silicon carbide, or another diamond face) in abrasive applications, at extreme temperatures, or under poorly lubricated conditions. Running UNCD T30 against a silicon carbide counterface reduces energy dissipation due to friction at the interface by 75 percent when compared to running silicon carbide against itself.

Because UNCD T30 is exposed to extreme shear forces when lubrication is lost, it has been engineered so that its bond strength to silicon carbide is stronger than the compressive strength of the silicon carbide itself. "Diamond is the world s hardest material and there s no better choice for durability on a surface that s susceptible to failure due to wear than UNCD T30," said ADT s vice president of engineering, Charles West.

With the addition of UNCD T30 to ADT s family of UNCD materials, there is now a diamond solution that is compatible with most fluid media and sealing applications. "Diamond is the material of choice when reliability matters. UNCD T30 is a game changer because instead of diamond being relegated to a small sliver of high end applications, diamond is now compatible with almost all material types and fluid combinations found in mechanical seals," said ADT s president, Neil Kane.

ADT gratefully acknowledges the National Science Foundation for its SBIR grant to develop UNCD materials for wear applications.