ABS New Floating Pontoons to Avoid Unnecessary Wear

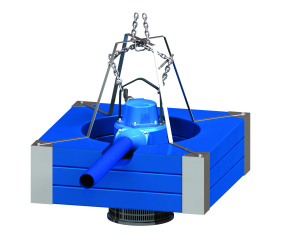

ABS introduces a new range of floating pontoons, which with its modular system will cover pumps from 50 to at least 500 kg.

ABS

When a submersible drainage pump is installed in a gravel pit or on a lake it is often required to have the pump floating close to the surface. The efficiency of the pump operating floating will in these applications improve and the wear of the pump can be kept to a minimum. ABS modular floating system makes it possible to build a floating pontoon to any of ABS dewatering pumps J54 to J405. The ABS modular floating pontoon system will be released autumn 2008.

The ABS floating pontoon system includes:

- Safe installation with approved and classified 2 part lifting chain mounted on the lifting bow

- Easy to install and to attach the pump before lifting it into operation. The chain is adjustable to get the pump in suitable levels

- Flexibility - few parts are used which can be built together on site to fit a variety of pump weights. You simply add on another floating module to increase the floating capacity

The ABS submersible drainage and sludge pumps J5-604, JS12-84 & JT15-250 are available in 0,5 to 56 kW. ABS dewatering pumps can be used for all dewatering needs – at construction sites, infrastructure, tunneling, gravel pits, sewage bypass as well as for stone cutting and fire fighting.

About ABS

ABS Group is a global supplier and offers pumps and rental services to the dewatering market. ABS is

also a global solutions provider in wastewater technology technology with a complete product portfolio

of pumps, mixers, aerators, compressors, control and monitoring equipment, and services. ABS Group

is present in more than 100 countries with 32 subsidiaries. ABS Group is a part of the Cardo group

which is listed on the Stockholm Stock Exchange.

Source: Sulzer Ltd.