ABS Expands the Mixer Range With a New Efficient Sludge Specialist

ABS Group proudly introduces the ABS submersible mixer RW 480; specifically designed for the major mixing functions during the homogenization of sludge and slurry.

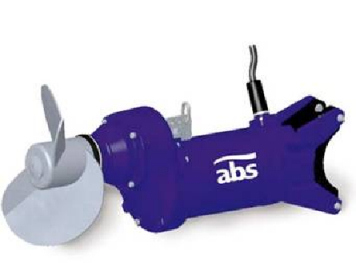

ABS Submersible Mixer RW 480

Reducing life cycle costs have been the development focus of the new ABS RW 480. The result is introduced in a mixer equipped with a special self-cleaning 2-blade propeller for blockage free mixing. A strong rotating turbulent flow is produced in radial and axial direction and the propellers combine all properties for the homogenization of sewage sludge which belongs to the intrinsic viscous substances.

The ABS RW 480 is designed for long operational life. The lubricated-for-life bearings has a calculated life of more than 100,000 operating hours and the high efficient gear box is built for continous operation.

Reduced energy costs are easily achieved with the high efficient 4-pole motor and the 1-stage helical gear box.

The reliability issues are further enhanced due to the highly efficient water pressure-tight encapsulated three-phase motor available with both 7.50 kW and 11.0 kW. The motor is equipped with a Thermo control system that protects the motor from overheat and automatically shutting it down before damage can occur.

The ABS submersible mixer RW 480 is used for mixing of viscous fluids containing solids in sewage treatment plants, biogas power plants, industry as well as agriculture.

About ABS

ABS Group is a global solution provider in wastewater technology with a complete product portfolio of pumps, mixers, aerators, compressors, control and monitoring equipment, and services. ABS also offers pumps and rental services for the dewatering market. ABS Group, with 1.800 employees and a turnover of 300 MEUR (2.7 billion SEK) in 2007, is present in more than 100 countries and has more than 32 subsidiaries. ABS Group is part of the Cardo group which is listed on the Stockholm Stock Exchange.

Source: Sulzer Ltd.