A Clear Approach to Energy Saving: Greentelligence Through Efficiency Calculations

How many euros do users really save in machine construction and plant engineering through the implementation of energy efficiency measures? Which measures bring what savings? Festo can now supply concrete and verifiable sample calculations for many applications.

Greentelligence in wastewater treatment: savings of €11,300 per year with pneumatic gate valves from Festo fitted on the pumps of the sewage treatment plant in Sindelfingen, Germany. (Photo: Festo)

For example, users can achieve savings of no less than 73% with vacuum handling units whose vacuum generators are controlled by air-saving circuits. The Festo vacuum generators OVEM and VADMI have been designed right from the start to incorporate these air-saving circuits and thus form part of Festo s portfolio of energy-efficient products and solutions.

Surprising results

Major savings of up to 32% can be achieved by reducing tubing lengths in small parts assembly and electronics operations, since in these applications, each time a pneumatic drive is actuated, the associated tubing needs to be pressurized and exhausted. Shortening the tubing between valves and cylinders by half produces this saving.

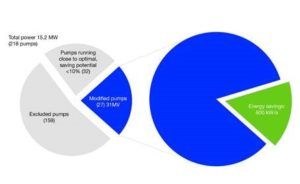

But even in cases where percentage energy savings are not in double digits, the efficiency gain in absolute terms can still amount to several thousand euros. The leading solution in this area is one which Festo specialists implemented in the wastewater treatment plant of the town of Sindelfingen. In wastewater treatment, correctly deployed pneumatics can increase the efficiency of electric drives. The gate valves offered by Festo reduce the energy requirements of the pumps, enabling savings of up to 11,300 euros a year.

It all depends on the application

In other cases, the principle is: "Energy efficiency in automation depends on the industrial application concerned," explains Dr. Axel-Andreas Gomeringer, Head of Innovation and Technology Management at Festo.

Any industrial application has its specific requirements with regard to technical criteria such as speed, load capacity, power to weight ratio, accuracy, control behaviour, torsional rigidity, efficiency or robustness and also economic criteria such as cost (purchase price, commissioning, installation) and operating costs (maintenance, service life, energy costs). Energy efficiency depends on the task at hand. "This task must be clearly defined before the user chooses a drive technology - electric or pneumatic or a combination of the two," explains Gomeringer.

Pneumatic and electric

A comparison between electric and pneumatic grippers shows how choosing the right solution depends on a clear definition of the task. If we consider the energy consumption during the gripping process, a pneumatic gripper will be superior to an electric gripper in applications involving long cycles and with just a small number of gripping operations.

A pneumatic gripper requires pressure only once to initiate continuous holding. No more pneumatic energy is required for the duration of the gripping operation. An electric gripper needs electricity for the entire duration of the gripping operation and can be more energy-efficient than a pneumatic gripper only if the application in question is composed of short cycles with many gripping operations.

Intelligent design

Engineering software helps in the dimensioning of systems. This allows components to be made smaller, avoiding an accumulation of safety factors. This saves effort and unnecessary costs in purchasing and operation.