Optimized Process Solenoid Valve for Gas and Liquid Applications

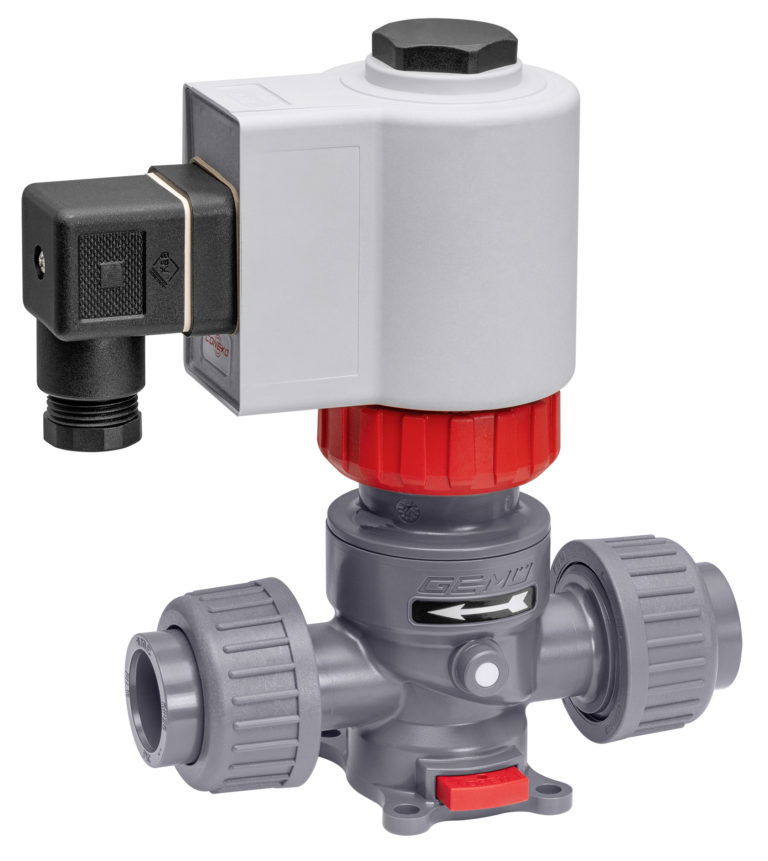

GEMÜ M75 pressure-compensated process solenoid valve. (Image source: GEMÜ Gebr. Müller Apparatebau GmbH & Co. KG)

In order to address customer requirements in a more specific way, the GEMÜ M75 pressure-compensated process solenoid valve is now available in a design for gas applications, as well as a design for liquid applications. Water hammers can therefore be clearly reduced, which increases product service life as well as plant reliability.

Dynamic and static pressure forces are compensated for by the innovative double bellows principle. As a result, the new valve with the very compact coil can be used for processes with an operating pressure of up to 6 bar. The fast operating times make the valve particularly suitable for dosing steps in mixing technology. Whether in the chemical industry, water treatment, washing and cleaning installations or electroplating.

Thanks to a wide range of high-quality body materials (PP, PVC and PVDF) and hermetic separation between the medium and the actuator using O-rings in various designs, the new process solenoid valve guarantees a reliable process sequence – including for corrosive media. The compact solenoid valve is suitable for nominal sizes DN 8 to 15 (and can be extended to DN 20 with an adapter) for open/close applications.