GEMÜ Valves Used to Combat COVID-19

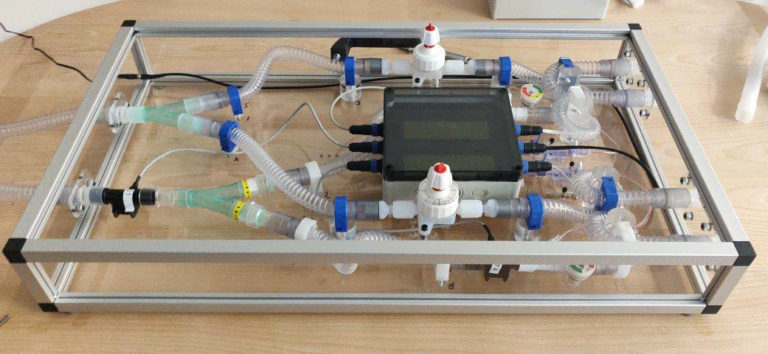

With a pragmatic solution, GEMÜ is supporting the development of a new system that doubles the existing ventilation capacity by allowing two patients to be ventilated by one ventilator at the same time. (Image source: GEMÜ Gebr. Müller Apparatebau GmbH & Co. KG)

The Institute for Manufacturing of Cambridge (IfM), which is part of the University of Cambridge's Department of Engineering, and the Royal Papworth Hospital in Cambridge are collaborating to develop a method for splitting a ventilator's air flow so that two COVID-19 patients can be treated simultaneously with one ventilator. Such a device would make it possible to double the capacities for the safe ventilation of patients for short periods.

One requirement imposed by medical professionals was that it had to be possible to individually measure and control the air flow to each patient. This was intended to ensure that a deterioration or improvement in the breathing of one patient would not affect the air supply or monitoring of the other patient.

In order to accomplish this, the IfM has developed a read-out meter, which makes it possible to measure the tidal volume for each patient in real time and monitor both the overall pressure and the air flow on the device. The individual fine adjustment of the air flow for each patient requires valves that can ensure the air/oxygen mixture is precisely metered and are also easily accessible.

In order to find a solution for these two challenges, the scientists collaborated with specialists from valve manufacturer GEMÜ. These specialists calculated the optimum flow rates for the air/oxygen mixture and recommended that the GEMÜ C67 valves in the nominal size DN8 be used, as these valves allow for a high air flow and simultaneously provide good manual controllability thanks to their low flow resistance. The design of the GEMÜ valves also plays an important role, as the handwheels are the only parts of the newly developed device located outside the housing, allowing doctors to individually adjust the air flow for each patient.

Tests of the "splitter" with artificial lungs have so far yielded very promising results, so that the first details about the apparatus, which was developed as a portable device, are now freely available on the IfM website. The website will be updated with the complete details of the design and testing once the device has been approved for use. This will make it possible to have the "splitter" copied across the world so that it can be used as needed, particularly in countries which, for a variety of reasons, do not have enough ventilators, to double ventilation capacities for short periods.

"We are very proud to have been involved in this project. The device developed by the Institute for Manufacturing of Cambridge will save lives, particularly in countries that do not have the means to procure a sufficient number of ventilators," says Gert Müller, Managing Partner at GEMÜ, about GEMÜ's contribution and the collaboration with the IfM.