Case Story: Seven Set-Ups Down to Two Saves Seven Hours per Bearing

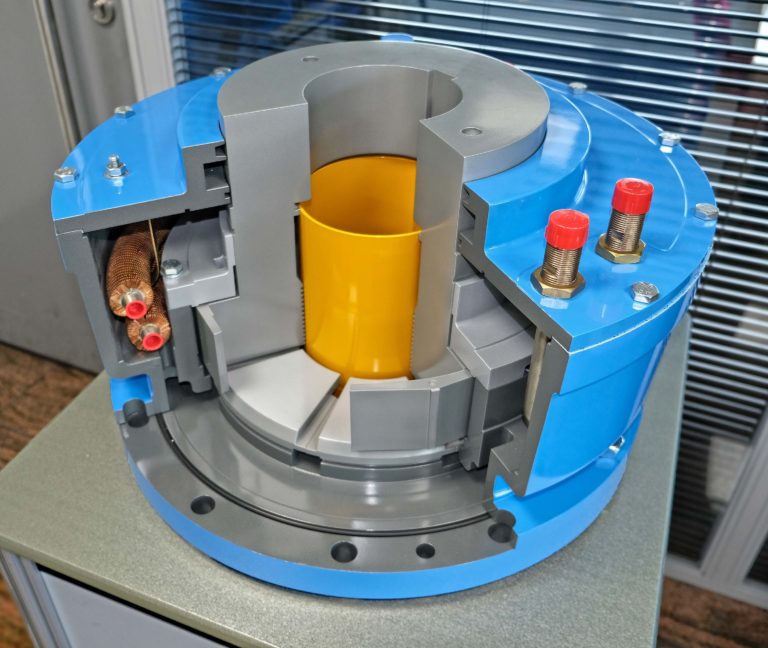

A cut-away view of a vertical bearing showing the complexity of build. Many parts are cylindrical, whereas in a horizontal bearing there are more prismatic components. (Image source: Kingsbury)

The mainstay of production on the shop floor at the South Shields factory is a pair of highly specified, 5-axis mill-turn machining centres built by Hermle, Germany, and supplied by Kingsbury, the sales and service agent for the UK, Ireland and Middle East.

Manufacturing Engineering Manager at Michell Bearings, Chris Kemp explained, "Until 2017 we produced all bearing parts that fell within a 600 mm cube in-house and subcontracted the rest. However, it was becoming increasingly difficult to find contract machinists to produce good quality parts in low volumes, at competitive prices. We therefore decided to invest in equipment that could machine cylindrical components up to 1,200 mm diameter and their prismatic equivalents."

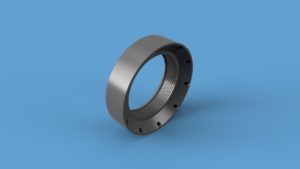

A 5-axis mill-turn machine was the preferred option, as this style of production centre offered a single-platform solution for producing all main parts that go into a vertical bearing as well as four principal constituents of a horizontal bearing. As ones and twos are generally machined, cutting out set-up time is especially important for cost effective production. The traditional process for machining a vertical casing formerly took seven operations. These are compressed into two set-ups on a Hermle mill-turn centre, eliminating five reclampings saving around seven hours per component.

Mr Kemp was familiar with the Hermle brand, as many such machines are in use at a nearby aero engine factory that he visited in the past. Other potential suppliers of mill-turn machines were also approached. The Hermle C 60 UMT with its 1,200 mm by 1,300 mm by 900 mm working volume was selected due to its robust construction and the high precision machining of which it is capable. This is crucial as bearings include tight tolerances, such as 25 microns maximum total runout over 400 mm for the perpendicularity of a face to the bore.

During cutting trials, the machine was also found to be capable of turning a 0.4 Ra surface finish on bearing faces, saving the time and expense previously involved in grinding and polishing them. "It is rare to find machines that are equally good at turning and milling, but Hermle machining centres are," Mr Kemp confirmed. That is the case even when roughing due to the ability of the turning table's 4,000 Nm torque drive to handle high forces up to 400 rpm without stalling.

Previously used by the Nuclear AMRC in Rotherham, the machine was transferred by Kingsbury to South Shields. Within three weeks it was in production and has been running 24/7 ever since. Mr Kemp said he had never seen a machine of this size installed in a factory so quickly. Part of the reason is its one-piece construction with triple guideway system above the work zone for the Y-axis gantry carrying the X-axis slide. This allows the machine to be craned in and placed on a foundation without having to be fixed to the floor. He believes the fact that major machine elements are not bolted together raises the milling and turning accuracy.

The high performance and reliability of the Hermle led Michell Bearings back to the same source in 2019 when a second mill-turn centre was needed to meet capacity demand. This time a new, slightly smaller C 52 UMT was selected with a 1,000 mm by 1,100 mm by 750 mm machining envelope.

An important part of the machine packages supplied by Kingsbury is the after-sales service provided by the agent and its principal, which Mr Kemp describes as "phenomenal". He advised that on the rare occasion there has been a failure, a telephone call to Kingsbury in Gosport often solves the problem.

If not, a diagnostic dump from the control is emailed to the agent, which can be forwarded to Hermle if necessary for a more in-depth analysis. If there are, say, three parts that are suspected to be causing the issue, the Kingsbury engineer will bring all three, usually the next day, allowing the correct part to be fitted so that the machine is quickly back in production.

"I have never experienced such good service before," Mr Kemp concluded.