Thordon SXL Bearings Keep Fans Cool in the Superdome

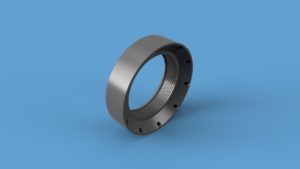

Thordon’s SXL pump bearings. (Image: Thordon Bearings Inc.)

The abrupt start and stop was tough on the pumps which led to the Superdome’s decision to opt for the variable frequency drives. The slow start and lack of consistent shaft speed with the VFDs led to increased periods of dry running causing the strain and eventual failure of the existing pump bearings.

The Superdome needed a robust replacement bearing material that was easily customisable into the pump design. Based on the recommendation of local company Pump Dynamics, Thordon’s SXL pump bearings were selected as the ideal solution due to the superior dry start up capabilities and abrasion resistance.

“Keeping the pumps running consistently and the stadium cool was our number one goal,” said Jim Bright, Sales Manager at Thordon Bearings. “Thordon SXL pump bearings are the proven choice for new vertical turbine pumps or can be easily designed into existing pump configurations to provide end users with exceptional bearing wear life. Since it is easily machined and installed we were able to provide the customer with our product quickly.”

Business Development Manager, Axel Swanson added “SXL is used extensively in over 80 countries and in a variety of industries wherever vertical turbine pumps are used. In this application, SXL’s dry start up capability was vital. The Superdome was able to increase the efficiency of the pump with the variable frequency drives and also lower their lifecycle costs with the SXL bearings.”

SXL was installed in one of the Superdome’s water cooling pumps at the beginning of the 2018 season, and it will be installed into the the remaining three pumps when they come up for scheduled maintenance.

Source: Thordon Bearings Inc.