Rheinhütte Pumpen Presents New Standardised Chemical Pump

Rheinhütte Pumpen launches a modern series with an added value for customers. Proven designs of the current product portfolio were critically reviewed and the latest technical possibilities explored to implement all the knowledge into the new plastic RCNKu+ pump with a strong technical know-how.

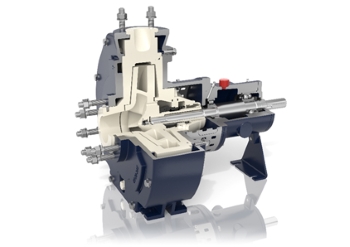

The new RCNKu+ is characterised by an innovative choice of materials and powerful hydraulics. (Image: Rheinhütte Pumpen)

During the period of intensive development, new production methods and materials were selected and optimal hydraulic systems designed using the most advanced simulation techniques. The result is a high-performance product with many new features providing a better serviceability, durability and economy.

A special highlight of the series is the mechanical seal Rheta, which has been completely redesigned. Thanks to an innovative material, the seal is completely metal-free and therefore completely corrosion-resistant. What is also new is that the standard version of the single-acting mechanical seal provides the possibility of a service rinsing. Thus, the mechanical seal can be rinsed when installed. This can be done during operation or at standstill, so that cleaning can be carried out whenever it is needed. The focus of the design was on the serviceability. Due to the innovative design, the assembly is very simple and can be learned intuitively. The critical parts are designed in such a way that incorrect installation can be excluded. Due to the sophisticated part concept, a conversion from single-acting to double-acting mechanical seal can be carried out quickly and easily. Only the parts for the second seal unit are needed.

The RCNKu+ is a high-quality and durable standard series with a smooth run. The stable bearing carrier has greasable rolling bearings already in the standard version and the bearings have high load ratings. A high-strength shaft material provides for low vibration and very high, transferable shaft power. The thick-walled plastic components of the hydraulics account for the longer service life of the product.

The new series is also very effective from the point of view of economy. In addition to high efficiency, a great importance was attached to the standardisation of parts when designing. The result is an extraordinarily compact stocking of spare parts, in particular with regard to the new mechanical seal. Here, the same sealing units are used for different sizes. Such stocking is an enormous advantage for customers who use different sizes. With regard to damage caused by wrong handling, this series can significantly reduce repair costs. For one thing, the impeller is independent of the direction of rotation, and for another, sacrificial parts are installed which prevent greater damage to the main pump parts.

Even the appearance of the new series was redesigned. The bearing carrier has a new design and the entire pump is painted in a modern navy.

The new pump is used in many industrial and chemical applications with abrasive and corrosive media. Its applications range from chemically contaminated water and wastewater applications to complicated processes such as Chloralkali electrolysis, Production of titanium dioxide, Flue gas cleaning in incineration plants and Steel and stainless steel pickling.

Source: ITT Rheinhütte Pumpen GmbH