Waukesha Bearings Provide Longer Life, Low Maintenance, Minimal Downtime

Waukesha Bearings is proud to announce the availability of its Multi-Lobe Semi-Floating (MLSF) bearings. The unique MLSF technology, which improves stability and reliability compared to conventional floating ring bearings, can extend the life of host equipment and surrounding parts.

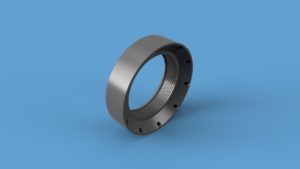

MLSF® Bearings (Image: Waukesha Bearings)

“Our MLSF design is specifically engineered to minimize vibrations, which promotes longer-lasting equipment and lessens the likelihood of early failures in the turbocharger or downstream equipment,” said Ken Bischof, Senior Development Engineer at Waukesha Bearings. “A failed bearing can lead to downtime for a replacement bearing, or worse, replacement of related equipment. A bearing system operating at an optimized temperature, which is cool enough to prevent coking yet hot enough to maintain optimum viscosity, can minimize both downtime and power loss.”

By designing the MLSF bearing system to operate at optimized temperatures with minimal vibrations, the life of the equipment and surrounding parts is extended. In addition to global customer service and Waukesha Bearings’ proven results, the MLSF bearings offer an ideal solution for smaller, high-speed turbomachinery, as well as for turbochargers in large diesel or natural gas engines.

Waukesha Bearings’ MLSF bearings, available for use with shafts as small as 0.5 inches in a single bearing or cartridge, can handle a static unit load as light as 10 psi (.07MPa) to a dynamic unit load exceeding 700 psi (4.8 MPa). The MLSF, which can handle multi-viscosity oils, is engineered to accommodate temperature ranges up to 300ºF (149ºC) with even higher temperatures available. The first Waukesha Bearings MLSF bearing, which has been in field operation for more than 30,000 hours, continues to surpass competitive bearing performance of only 500 hours in the same application.

Source: Waukesha Bearings Corporation