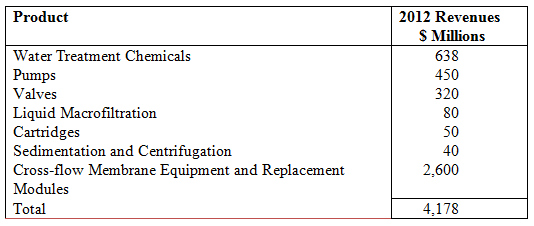

$4.2 Billion Desalination Market for Pumps, Valves, Filters and Chemicals

The market for pumps, valves, filters and chemicals for use in desalination will increase at near double digit rates from a 2012 level of $4.2 billion. This is the conclusion reached by the McIlvaine Company in aggregating forecasts in a number of its reports.

McIlvaine Company

Treatment chemical cost averages 0.03 $/m³ of capacity in seawater, reverse osmosis (RO) systems and 0.02/ $/m³ in thermal systems. There is substantial use of scale inhibitors in thermal systems. Acids and antifoams are used in MSF systems. Cleaning chemicals are a substantial investment where RO is employed. The present desalination market is 70 million m³/day with a projection of 100 million m³/day by 2015. The present water chemicals market is $638 million per year rising to $912 million in 2015.

The amount of water being pumped in desalination systems is presently only about one percent of the amount being pumped for all the world s drinking supplies. On the other hand, the high pressure pumps needed for reverse osmosis are an order of magnitude more expensive than those used for drinking water transport. So, of the $6 billion 2012 market for pumps for drinking water, $450 million is attributable to desalination. Of the $3.4 billion market for valves for drinking water, $250 million is attributable to desalination. This does not include the valves used for thermal treatment which add another $70 million.

Prefiltration for the reverse osmosis systems and initial purification of water which will be evaporated in thermal systems is accomplished with liquid macrofiltration and cartridges. Automatic back wash filters and sand filters are frequently used. Liquid wastes are dewatered in filter presses.

Cartridges are used to remove particles which are too small to be captured in liquid macrofiltration equipment but too large and plentiful to be handled by cross-flow membranes. There has been a high replacement frequency on cartridges.

An alternative to liquid macrofiltration is sedimentation. Clarifiers and dissolved air flotation systems are selected for a number of systems. The desalting takes place in either thermal systems where the water is evaporated or by separation with cross-flow membranes. Reverse osmosis does the final separation. Macro or ultrafilters are often used to pre-filter and protect the RO membranes.

Source: The McIlvaine Company