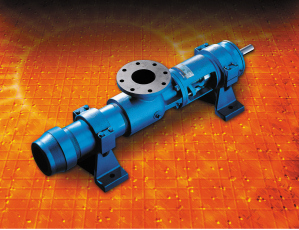

L-Frame Progressing Cavity Pumps Handle a Wide Variety of Applications

Moyno offers the Moyno L-Frame Progressing Cavity Pump for dependable performance and maximum operating efficiency.

These versatile pumps are ideal for handling clean, thin, shear-sensitive products to viscous, corrosive, abrasive slurries and sludges in chemical, petrochemical, water and wastewater treatment, mining, food processing, pulp & paper and general industrial applications.

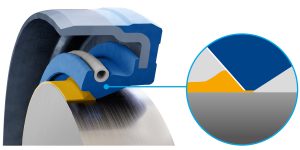

With a variety of models and an extensive range of materials of construction, Moyno L-Frame Pumps offer tremendous application versatility. Standard flange models feature a modular design with a simple pin-type universal joint for easy maintenance. Open throat models are also available. All Moyno L-Frame Pumps are available with a wide variety of drive options, sealing configurations, motors and controls to address critical application requirements.

Additional L-Frame features include:

- Non-pulsating, metered flow

- Long life even in abrasive applications

- Quiet, vibration-free operation

- Easy, on-site maintenance

- Low product shear

- Viscosities over 1,000,000 cps

- Capacities to 450 gpm

- Pressures to 2,100 psi

- Handles entrained air and gases without vapor locking

Source: Moyno