Testing Valves Without Disrupting the Process Line

Partial stroke testing is common practice in many process plants enabling valves to be tested without causing major interruption or down-time to the production process.

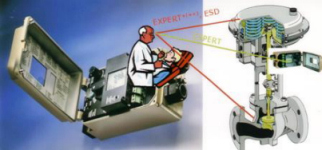

Samson Controls

Shut-off valves, usually activated by a solenoid valve, in a safety loop are the preferred devices allowing operators to shut down process lines in the event of an emergency.

As part of their wide range of control valves, positioners and accessories, Samson Controls offers a range of Electro pneumatic positioners which allow stroke tests to be carried out without disrupting the process line. For example, their type 3730-3 positioner incorporates an ESD (Emergency Shutdown) function to enable stroke test to be carried out without the need for shutting down the process line. It can be mounted on the valve in addition to the solenoid valve, or to replace it and enables the valve to be moved precisely to follow the set point within the valves working ratio. The partial stroke test is completely integrated into the positioner to detect a sticking valve, caused for example, by corrosion.

Test schedules can be as flexible as required and prolonged if necessary to suit specific application requirements, while test validation can be performed simply by using the corresponding instrumentation and initiating it over a commonly available SIS logic solver.

Source: SAMSON Controls Ltd.