Allweiler Establishes New Global Service Centers for High-Pressure Pumps

Allweiler’s new global service centers for its Emtec series of pumps will enable the company to more efficiently serve tool-machine customers around the world. These high-pressure pumps are used primarily to move critical cooling lubricants in tool machines.

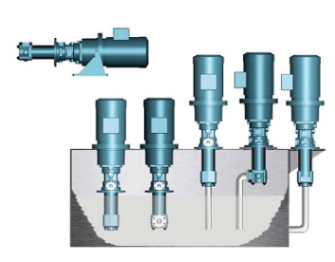

EMTEC high-pressure pumps are ideally suited for use in tool machines.

Service centers in Europe, the United States, and Asia will provide Allweiler customers with on-site advisory and maintenance services plus emergency service and rapid spare parts delivery. Allweiler is subsidiary of Colfax Corp.

Emtec high-pressure pumps are used primarily in tool machines to move emulsions, cutting materials, and cooling lubricants. Working together with international parent company Colfax Corporation, Allweiler AG has established special service and support centers on three continents as a way to reduce costly downtime of tool machines. The centers are located at Allweiler headquarters in Radolfzell in southern Germany; at Colfax in Monroe, North Carolina; and in Wuxi, China.

Emtec Global Service provides pump users with immediate help and support, usually within 24 hours, but not longer than 48 hours. The service is available worldwide, regardless of where the tool machine is located. Trained and experienced experts in each region respond quickly, provide rapid emergency services, and send ready-to-use replacement pumps within short reaction times. According to Dr. Michael Matros, Chairman of Allweiler and Colfax Senior Vice President: “Emtec pumps and our specialized Global Service help our customers maximize the availability of their machines and simultaneously minimize the total cost of ownership. Twenty-four-hour operation of tool machines is now possible without the operator needing to maintain stocks of spare parts at great expense."

The range of services covers everything from support during installation and start-up to on-site diagnostics and optimization of existing installations. Furthermore, Allweiler stands ready to provide trial and replacement pumps. If requested, the company will also analyze components or perform repairs in the specially equipped service and support centers. Allweiler service and support centers offer training for maintenance and service technicians, customized service and maintenance contracts, and centralized storage of pumps and spare parts for individual customers.

Emtec screw pumps are designed to move emulsions, cutting oils, and cooling lubricants of all types (maximum pressure 130 bar) while maintaining high efficiency, low pulsations, and low noise. They are ideally suited for use with tool machines that have internally cooled tools and for high-performance grinding. A single version permits installation both in and on a container as well as dry installation in vertical and horizontal positions.

About Allweiler

Allweiler AG is the oldest German pump manufacturer and the European market and technology leader for centrifugal, propeller, screw, progressing-cavity, cogwheel, rotary lobe, macerators and peristaltic pumps. Headquartered in Radolfzell and with locations in Bottrop and Gottmandingen, Allweiler owns a foundry, produces its own stators and manufactures ready-to-use fuel and lube-oil skids and rinsing-water facilities for commercial marine, oil & gas, chemical processing, specialty chemical and waste and wastewater applications.

About Colfax Corporation

Colfax Corporation is a global leader in critical fluid-handling products and technologies. Through its global operating subsidiaries, Colfax manufactures positive displacement industrial pumps and valves used in oil & gas, power generation, commercial marine, global naval and general industrial markets. Colfax’s operating subsidiaries supply products under the well-known brands Allweiler, Fairmount Automation, Houttuin, Imo, LSC, Portland Valve, Tushaco, Warren and Zenith. Colfax is traded on the NYSE under the ticker “CFX.”

Source: ALLWEILER GmbH