Wilden T-Mag Mag-Drive Pumps Ideal for Caustic Recirculation in Metal Plating Industry

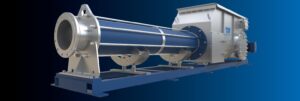

Wilden, announced that its T-Mag Mag-Drive pumps are ideally suited for use in cleaning caustic recirculation lines in the aggressive environments found in the metal plating and coatings manufacturing industry.

Because various types of caustics are used in these types of facilities, it is imperative that the recirculation lines are entirely free of previous product to prevent cross-contamination.

The T-Mag Mag-Drive pumps, which are available in sizes from 1/2 to 5 horsepower, come standard with a patented additional fluid flow path around the bushing. This additional path allows the process fluid, or air, to cool the bushing of the impeller from the outside, while continuing to offer the internal spiral cooling channel found on most magnetic-drive centrifugal pumps. This unique heat-dissipation technology prevents the heat build-up that so often damages or completely disables the shaft bushing.

Other features of Wilden T-Mag Mag-Drive pumps are double-end supported ceramic shafts; adjustable flanges; PP, PVDF and ETFE liquid paths; seal-less design; dry-run capabilities; high-performance magnetic couplings; computerized fluid-stream patterns; and a compact footprint.

About Wilden

Jim Wilden, founder of Wilden Pump and Engineering Co., revolutionized the pumping industry when he invented the air-operated double-diaphragm pump in 1955. Since then, Wilden has created a line of distinctive pumps that have proven to be trustworthy solutions to pumping applications in a wide variety of industries. Wilden—headquartered in Grand Terrace, California, USA—is a member of Dover Corporation’s Pump Solutions Group (PSG).

Source: Wilden