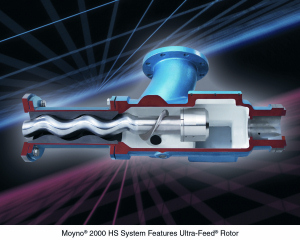

Moyno 2000 HS System Features High Efficency Progressing Cavity Pump

The Moyno 2000 HS System is a cost-effective alternative to expensive, high-maintenance piston pumps and conveyors for dewatered sludge transfer in municipal and industrial wastewater treatment as well as other high solids content fluids.

Moyno 2000 HS System

The Moyno 2000 HS System utilizes the advanced Moyno® 2000 G4 progressing cavity pump with proprietary Ultra-Feed® rotor technology.

The high-efficiency G4 progressing cavity pump’s 45° inlet lowers friction loss and provides for gentler handling of the product. It also features a universal joint that is out of the fluid flow path for unobstructed flow to the pump cavity inlet. The G4 progressing cavity pump design results in lower overall system pressure and its constant, non-pulsating flow imparts less stress on piping, machinery and drive systems.

The patented auger feed on the Ultra-Feed rotor head smoothly stuffs product directly into the cavity without obstruction. The Ultra-Feed rotor configuration is designed to enhance flow of high solids content materials and optimize volumetric efficiency.

Typical applications for the Moyno 2000 HS Systems include:

- Scum transfer

- High viscosity, solids-laden slurries and sludges

- Thick adhesives

- Municipal sludge in excess of 10% solids

About Moyno

Moyno, Inc., a part of the Fluid Management Group of Robbins & Myers Inc, is a leading manufacturer and marketer of Moyno progressing cavity pumps, multiphase fluid transfer systems, grinders and controls. It has an extensive worldwide stocking distribution network that serves a wide range of industries including water and wastewater treatment, pulp and paper, chemical, food, pharmaceutical, mining, petrochemical, and oil and gas recovery.

Source: Moyno