Cost Calculation for Waterjet Cutting Projects

Operators of a Waterjet system often are confronted with the question of the costs this cutting system might cause. How is it possible to estimate which parameters would have to be used to conclude a project efficiently and profitably?

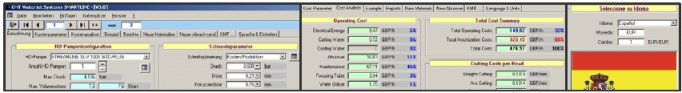

The software update SMARTLINE 3.0 provides you with a simple and all encompassing cost analysis

Waterjet cutting technology offers an amazing range of possible utilisation. Operators of a Waterjet system often are confronted with the question of the costs this cutting system might cause. How is it possible to estimate which parameters would have to be used to conclude a project efficiently and profitably? All essential factors, such as STREAMLINE™ pump type, cutting parameters, selection of material and of material thickness, cutting velocity and cutting quality as well as costs of consumables, maintenance and wear and labour costs as well as operation costs can be factors of the costs analysis for the calculation of the costs to be expected.

Set parameters in 5 windows – print result – finished!

- Window “computation“

Under “Intensifier configuration“ the STREAMLINE™ pump is selected. Parameters such as max. performance, max. pressure and max. volume flow are pre-set. Cutting pressure, nozzle diameter, quantity of abrasive, abrasive sand and the number of cutting heads complete the information. In the box “material and quality selection“ the cutting material including cutting thickness and desired cutting quality is determined. The drop down menu “Cutting Objective“ situated below the header “cutting parameters” allows you to choose between the options costs / production, minimal costs and maximum production.

- Window “cost parameter“

Here you can enter the costs of consumables such as electricity and water. Costs of maintenance and wear as well as labour costs and acquisition costs are additional parameters considered in this costs analysis.

- Window “cost analysis“

This window shows the total costs and additionally, the operating and amortization costs, as well as the costs per cutting head.

- Window “example“

Under „definition of contour of the sample part“ you can enter information on the length of the sample part, number of the cut-ins and the parts as well as on the drill radius.

- Window “reports“

On this page the user decides on the selection of this report. The result can either be printed directly or exported to a file.

To test new materials – simply enter test codes and calculate costs

In the windows “new materials“ and “new abrasive sand“ the processing codes respectively the abrasive factor of unknown materials can be determined. After the definition of all relevant cutting parameters, SMARTLINE calculates the desired figures. In this way, the user obtains an approximate value for the cutting costs to be expected.

Integrated help menu and 6 language versions available

The accompanying help explains each individual window as well as all entering options thus supporting the user in his individual cost calculation. The desired language is selected in the window “language and units”. The currency symbol and rate of exchange can be edited here. With the button “save defaults” these settings will be used in all further calculations. SMARTLINE 3.0 is available in the following languages: English, Spanish, Swedish, Finnish, Greek and German.

Source: KMT Waterjet Systems Inc.