Tencarva Acquires Innovative UniGuard Machine Guard Line

Tencarva Machinery Company, headquartered in Greensboro, recently acquired the durable, corrosion-resistant UniGuard Machine Guard line of products with the firm’s agreement for the purchase of the assets of Computer Cut Inc., of New Bern, N.C., according to Rod Lee, Tencarva president.

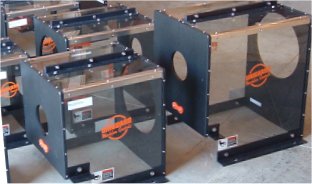

The ANSI pump guard, properly installed in line, protects workers from accidental injury (photo: Tencarva)

As a part of the agreement, Tencarva brought on board Ken Brisk, the company’s former owner and product’s inventor, as UniGuard manager for Tencarva. Computer Cut previously made guards that cover rotating shafts in the New Bern location, but now Tencarva has set up the manufacturing of that product in the Greensboro facility, with Brisk in charge of the UniGuard production.

The innovative UniGuard Machine Guard is used primarily to enclose a rotating coupling connecting the shafts of the driven equipment and the driver (usually an electric motor) and the driven item to prevent harm to people working around the equipment. Made from sturdy polyethylene, these guards can be custom designed in any size--small or large—to cover the shaft lengths and diameters required. The guards can be customized for users needing access doors for coupling maintenance (such as greasing), or with clear windows for viewing the rotating elements.

The UniGuard Machine Guard was created in 1994 when Brisk was given the task of overseeing that the machine guarding at the facility where he worked was brought up to current standards. With over 30 years of industrial maintenance experience, primarily in the power and chemical fields, Brisk was a maintenance planner for Hydra-Co Operations, which operates a biomass power plant in eastern North Carolina. Hydra-Co Operations was later acquired by CMS Generation.

Brisk explains, “I checked with numerous suppliers for a readily available OSHA (Occupational Safety and Health Administration) compliant machine guard, but was bewildered that even the largest industrial supplier had nothing to offer. I realized that there was a need for an easy-to-use and economical machine guard that could be sold through distributors that carried the type of equipment they are used on.”

Working in his garage and on weekends, Brisk refined his initial ideas, and after two years, in January 1997, was granted patent protection for Type CGU-Machine Coupling Shaft Guard. Brisk points out, “Simple in concept, this nonmetallic coupling guard allows distributors to offer an off-the-shelf, trim and fit, economically priced, OSHA compliant coupling guard right off their shelf.”

Teaming with Tencarva Machinery Company, Brisk has broadened the UniGuard product line, and today UniGuard Machine Guards are available to fit almost any application. The product line includes direct drive coupling and shaft guards, as well as vertical and horizontal V-belt guards.

Harry Taylor, Tencarva vice president of operations, explains, “Many guards are simply a piece of bent metal with open ends. These may be called a guard, but offer very little real protection as the rotating shafts are exposed on either end. They can be flimsy, and the openings are large enough that fingers or hands can be inserted (usually by mistake).

“In addition, metal guards rust. The UniGuard is made from a polyethylene that cannot rust and is not affected by the ultraviolet rays of the sun, so it can be used outside. This guard also can be used in chemical environments where stainless steel material had been required (giving the UniGuard tremendous price advantage).”

He continues, “The UniGuards are designed for easy installation. The guards can be purchased with the proper diameter and style to cover a shaft, coupling or belt drive. Many of the direct drive guards are adjustable in length using common hand tools. The guards are split (clam shell like) so they can be installed and removed. Horizontal V-belt guards have slip off backs for easy removal.”

The UniGuard comes in many standard sizes, but can be economically built for custom applications, and is constructed of sturdy polyethylene. The unit can also be thought of as a “little plastic house,” which lends itself for many other applications as guards or covers.

The UniGuard fully encloses rotating shafts so people can safely work around the equipment. UniGuard Machine Guards comply with OSHA standards and meet ANSI (American National Standards Institute) regulations that do not allow for openings to be greater than ¼”. (OSHA does not set a standard for the size of an opening with regards to machine guarding only ANSI does).

Taylor emphasizes, “We find that many maintenance departments will make their own guards from metal. They may do this thinking they are saving money! Before we started using the UniGuard in our applications, I thought the same. I found that it takes a lot of time to design, locate and order material, paint and install. Even then, if someone were injured, whoever designed and built the guard had to be concerned whether the guard was designed properly. The UniGuard is OSHA/ANSI compliant and economical.”

Tencarva is a distributor specializing in liquid process, compressed air, vacuum equipment and custom-designed systems for the industrial marketplace. Tencarva is dedicated to providing the highest quality process machinery to all industry coupled with superior customer service and integrity.

Founded in 1978, Tencarva Machinery is committed to providing superior service by supplying innovative engineering assistance, professional equipment selection, competitive deliveries and parts availability, and preventive maintenance and repair services to all its customers. Tencarva has 23 branches in the U.S., including Arkansas, Florida, Maryland, Mississippi, North Carolina, South Carolina, Tennessee and Virginia.

Source: Tencarva Machinery Company