News from the IFAT 2005 – Part 2

In the second part of the live report from the IFAT 2005 which took place in Munich, impeller.net again sums up the news from well-known manufacturers and their product highlights.

Reacting to the changed conditions over the past years, ITT Flygt now has entirely optimized solutions. R&D include - besides pump technology - sump geometry and control technology. The highest possible efficiency is to be achieved with optimized component settings.

Having had the goal to avoid the sedimentation of solids, Flygt optimized a fluidic pump sump design

and refined it all the way to start of serial production. The Compit works best in pressure dewatering while the TOP pump sump was developed for municipal pump stations.

Whenever the capacity of a barrel pump is not sufficient, centrifugal immersion pumps with high delivery flow rates and submersion depths are a suitable alternative for transferring and circulating corrosive and abrasive fluids with a viscosity of up to 2.500 mPas. The new Flux pumps of the F 640 series are vertical centrifugal pumps for wet or – in special versions - also for dry installations that consist of a inner and an outer tube. The drive shaft is supported within the inner tube and a mechanical seal in separates the liquid from bearings and upper shaft.

The liquid is transferred – either with a conical or a closed impeller between the inner and the outer tube towards the discharge nozzle which at the same time ensures optimized cooling of the line shaft. The pump is made of stainless steel 316 Ti (S). The versions made of plastic have an inner tube with steel core which ensures to minimize the linear expansion even at high temperatures. This guarantees the secure functioning of the mechanical seal. The plastic coating is for the protection against abrasive fluids, the steel core ensures the sturdiness of the pump by taking in inner and outer hydraulic and mechanical forces. Preferred applications are the chemical industry, process engineering, surface treatment, electroplating, fresh and waste water treatment.

The liquid is transferred – either with a conical or a closed impeller between the inner and the outer tube towards the discharge nozzle which at the same time ensures optimized cooling of the line shaft. The pump is made of stainless steel 316 Ti (S). The versions made of plastic have an inner tube with steel core which ensures to minimize the linear expansion even at high temperatures. This guarantees the secure functioning of the mechanical seal. The plastic coating is for the protection against abrasive fluids, the steel core ensures the sturdiness of the pump by taking in inner and outer hydraulic and mechanical forces. Preferred applications are the chemical industry, process engineering, surface treatment, electroplating, fresh and waste water treatment.

Another highlight are the new brushless motors for barrel pumps. They have a combined on/off switch and easy to use speed controller. These motors have an EC-Type-Examination Certificate No. PTB 03 ATEX 1042. There is additional safety due to no-volt release safety circuit monitoring the power and preventing from any unintentional re-start of the pump which guarantees optimum security. Speed, voltage and temperature are monitored electronically. The motors are ideal for either continuous or short-term use, or even precise dispensing operations.

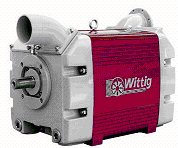

Gardner Denver Wittig redesigned its liquid ring compressor vacuum pumps for suction vehicles – the Wittig Aqualine series. The Wittig Aqualine series comprises seven types designed for flow rates up to 3.100 m³/h. These new vehicle equipment units stand out not only for their particular attractive appearance and clear-cut shape which merges harmonically with the vehicle on which they are installed but also for their performance and reliability. The on-piece cast housing with integrated suction-compression connecting ducts requires very little fitting space. A further advantage is the unit’s double-end drive shaft, which permits either clockwise or counter-clockwise drive rotation. Despite their compact design, the units achieve maximum flow rates. Their low weight is attributable to the use of aluminium and the state-of-the-art integrated design principle. Liquid ring compressor vacuum pumps can be driven by the vehicle engine via auxiliary drive. Alternatively, a hydraulic motor may be flanged directly to the unit.

Gardner Denver Wittig redesigned its liquid ring compressor vacuum pumps for suction vehicles – the Wittig Aqualine series. The Wittig Aqualine series comprises seven types designed for flow rates up to 3.100 m³/h. These new vehicle equipment units stand out not only for their particular attractive appearance and clear-cut shape which merges harmonically with the vehicle on which they are installed but also for their performance and reliability. The on-piece cast housing with integrated suction-compression connecting ducts requires very little fitting space. A further advantage is the unit’s double-end drive shaft, which permits either clockwise or counter-clockwise drive rotation. Despite their compact design, the units achieve maximum flow rates. Their low weight is attributable to the use of aluminium and the state-of-the-art integrated design principle. Liquid ring compressor vacuum pumps can be driven by the vehicle engine via auxiliary drive. Alternatively, a hydraulic motor may be flanged directly to the unit.

The Dri-Prime from Godwin, the specialist for portable pumps, is a centrifugal pump designed for applications in construction, mining, environmental and industrial markets and the quarry industry as well as many municipal sewer bypass and general de-watering applications. The automatic self-priming pump set is capable of handling sludge and solids to 125 mm. The new Dri-Prime HL pumps feature high heads up to 183 m.

Gorman-Rupp has redesigned the RAMPARTS air driven diaphragm pump from the iC series. The rugged single diaphragm construction and extra-thick pump casing of Gorman-Rupp Air Driven Diaphragm pumps stand up to the abuses of the most demanding sludge and slurry applications. When handling abrasive fluids they are the ideal alternative to eccentric or double diaphragm pumps. Another advantage is the independent setting of the stroke rate and the operating pressure which allow for the adjustment of the flow to the operating conditions. Air driven diaphragm pumps are capable of operating dry, on suction lifts up to 20 feet and handling high solids contents up to approximately 70%.

Efficiency and reliability are the characteristics that describe the new S series of wastewater pumps by Grundfos. Depending on the application these pumps can be equipped with a single or multi channel impeller or even a SuperVortex impeller. The latter ensure the delivery of wastewater even with small pump sizes. The patented SuperVortex impellers also called Wings avoid the common vorticity of the fluid. This results in high efficiency at consistent operating safety. The flow is outside of the impeller so fibers or similar particles can easily pass by the pump. Downtime is therefore avoided. Sand and corrosive particles contained in wastewater normally cause wear and therefore minimize the efficiency or even block the impeller. The Grundfos S series wastewater pump has a SmartTrim impeller adjustment to avoid that. The gap between the impeller and the casing can be adjusted from the outside through handling only three screws. This way the optimum efficiency is reset with little effort. On top of that the pump has a water proof and corrosion free connection in standard version or ex-certification according to ATEX, a water proof motor with temperature sensor and a SmartSeal for leakage free connection.

Efficiency and reliability are the characteristics that describe the new S series of wastewater pumps by Grundfos. Depending on the application these pumps can be equipped with a single or multi channel impeller or even a SuperVortex impeller. The latter ensure the delivery of wastewater even with small pump sizes. The patented SuperVortex impellers also called Wings avoid the common vorticity of the fluid. This results in high efficiency at consistent operating safety. The flow is outside of the impeller so fibers or similar particles can easily pass by the pump. Downtime is therefore avoided. Sand and corrosive particles contained in wastewater normally cause wear and therefore minimize the efficiency or even block the impeller. The Grundfos S series wastewater pump has a SmartTrim impeller adjustment to avoid that. The gap between the impeller and the casing can be adjusted from the outside through handling only three screws. This way the optimum efficiency is reset with little effort. On top of that the pump has a water proof and corrosion free connection in standard version or ex-certification according to ATEX, a water proof motor with temperature sensor and a SmartSeal for leakage free connection.

In the center of the presentation of Herborner Pumpenfabrik are the UNIGUM pumps. After successfully passing long-term tests the technology of the gummed pump is now ready for mass production. The wear resistant design makes the pump especially suitable for applications like handling of sand-containing or mud-containing water. All inside areas exposed to abrasion including the further developed vortex are protected by a special gumming. The normally very destructive wear of regular pump designs is hardly noticeable in this pump.

In the center of the presentation of Herborner Pumpenfabrik are the UNIGUM pumps. After successfully passing long-term tests the technology of the gummed pump is now ready for mass production. The wear resistant design makes the pump especially suitable for applications like handling of sand-containing or mud-containing water. All inside areas exposed to abrasion including the further developed vortex are protected by a special gumming. The normally very destructive wear of regular pump designs is hardly noticeable in this pump.

More power and higher efficiency with lower operating costs – that was the central focus of development for the new submersible sewage pump series KX 44 to KX 86 by HOMA. The new powerful hydraulics available up to a nominal size of up to DN 400 discharge size ensure a higher pressure, higher flow and a higher efficiency. The pumps can either be wet or dry installed and on request are available with Ex-certification according to ATEX.

With the C series HOMA offers all its electric submersible pumps for waste water and sewage pumping in cast stainless steel. This extremely wear resistant material makes it possible to apply these pumps to fluids that contain abrasive solids or fiber or even chemically corrosive particles.

The new mixer and horizontal flow accelerator series HRS/HRG and HRM/HRL were especially designed for use in municipal and industrial sewage treatment, process engineering and agriculture.

Source: Messe München GmbH