Large Rotary Lobe Pumps

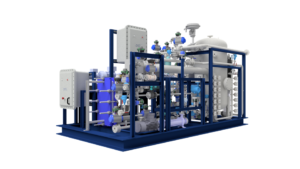

SSP Pumps has launched the Series A and G ranges of rotary lobe pumps (RLP’s), which are amongst the world’s largest pumps of this type. With flow rates of up to 680 m³/h the pumps are designed for high-volume transfer applications required in the chemical, food, pharmaceutical and waste treatment processes.

SSP Pumps has a long and distinguished history with the innovation of large pumps, being the first company to introduce 125mm diameter ported RLP’s, followed by 150mm, 200mm, 250mm and 300mm diameter ported pump models.

Large does not simply mean the scaling up of smaller pump models. Both series are specifically engineered to order, having five pump head displacements ranging from 550 litres/100rev to 2270 litres/100rev, differential pressures up to 10 bar and port sizes from 150mm to 300mm in diameter.

From initial enquiry the specification of the pump will be engineered to ensure the most appropriate pump is provided to meet application requirements. The pumps provide high efficiency and low energy consumption, smooth low-shear action, cost effective easy maintenance and the ability to pump abrasive media and media with large solids.

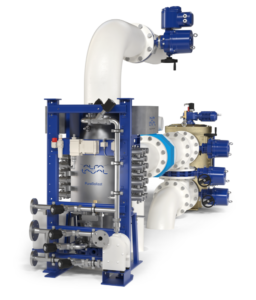

The Series A pumps, with metallic wetted components manufactured from stainless steel, can handle from low to high viscosity pumped media and are ideal for delicate media and where organic solids in suspension, creams, froths, gels, emulsions and mixtures are to be pumped.

Series G pumps, with ductile iron metallic wetted components, operate within general industrial and waste water treatment processes providing a good tolerance of suspended solids including fibrous matter. Series G pumps have proven ability in handling a full range of sludge thickness with rag and grit included.

The high efficiency of the pumps is achieved by maintaining high accuracy and repeatability of component manufacture, thus maximising shaft rigidity and minimising the effects of thermal expansion within the pump gearbox. This combination allows the optimum pump head geometry to be achieved, maximising efficiency.

Series A pumps, in standard specification, have stainless steel tri-lobe rotors available in three temperature ratings, allowing the pump to be operated at maximum temperatures of 70°C, 130°C and 200°C for both process and CIP.

Series G pumps’ standard specification tri-lobe rotors are manufactured from ductile iron or a metal insert covered with either NBR or urethane, both giving long term wear resistance. The urethane rotors are provided with grit channels to improve rotor life. Series G pump casings may be supplied fitted with hardened, replaceable wear plates (standard on sludge pumps), which can be replaced in situ with minimal pump dismantling.

About SSP Pumps

SSP Pumps is a premium brand of Alfa Laval Pumps Limited and offers the industry’s most comprehensive rotary lobe pump (RLP) portfolio, for applications requiring a higher level of specification interface. The range of high-quality pumps are channelled exclusively through a selected worldwide distribution network, and directly from Alfa Laval’s group centre of excellence for rotary lobe pumps, located in Eastbourne, England. The brand has a long and distinguished history. SSP Pumps Limited, was founded in Eastbourne in 1958. It was the first company to introduce 5 inch, followed by 6, 8, 10 and 12 inch diameter ported RLPs as well as the first with ductile iron RLPs. The company was acquired by Alfa Laval in 1987 and a new company, Alfa Laval Pumps Ltd was formed.

Source: ALFA LAVAL Corporate AB