Software streamlines planning and procurement of centrifugal pumps

The pump selection software Spaix does not only optimise the selection and configuration of the best pump, but also the supply and procurement process. Therewith the software package on one hand is a planning tool for engineering, on the other hand it is suitably very well to the manufacturer side in order to provide a quotation efficiently. The following example of a pump station from the Degussa AG demonstrates, how Spaix works.

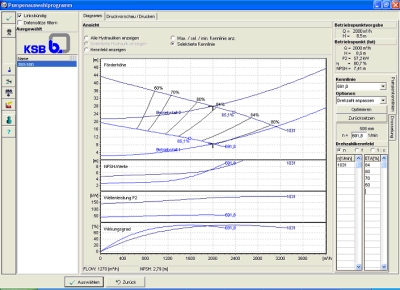

Spaix calculates the optimal speed for different operating conditions

In general there are two options to generate a pump catalogue with Spaix. Either one feeds and maintains all information with the Data Maintenance Program through the desktop or one reads a catalogue data file through a standardized interface. The second option is for system designers and engineers the more interesting solution. With this background the German industrial associations VDMA (engineering industries) and VCI (chemical industry) compiled the norm “VDMA Einheitsblatt 24278”. The norm contains the specification of data exchange between pump manufacturers at one side and operators and engineering at the other side. It includes the description of a catalogue and a project interface. The related pump catalogues can be ordered directly by the manufacturer. Both interfaces of the VDMA Einheitsblatt are integrated in Spaix, furthermore the program supports other data exchange formats.

The sample project includes a pump station with three identical pumps, whereby in the standard operation only one pump works. Pump Two is planned for the peak load operation, while the third is a stand-by pump to switch on in emergency operation.

Two operation modes have to be considered for the pump selection. In operation mode 1 the pumps have to transport the water from the suction side tank through the pipe A of the discharge side. In operation mode 2 an alternative pipe B has to be used.

| Numbers of working pumps | Total flow rate | Total head | Geodetic head | |

| [m³/h] | [m] | [m] | ||

Operation case 1 (Pipe A) | 1 | 2000 | 8,5 | 2,3 |

| 2 | 4000 | 9,1 | ||

| 3 | 6000 | 9,7 | ||

| Operation case 2 (Pipe B) | 1 | 2000 | 28,0 | 21,5 |

| 2 | 4000 | 29,4 | ||

| 3 | 6000 | 31,2 | ||

Table 1: For the selection of the pump station two operation modes have to be considered.

In the first step the hydraulic selection will be made for the operation mode 2 in the Spaix PumpSelector. The model range can be specified by the choice of the area of application according to the manufacturer’s recommendations. In the example the suitable pump range was already known for the given application. The main task was the calculation of the different operation modes considering the pump control and regulation.

The quit different head of the duty points of mode 1 and 2 require the exact keeping of two different speed fields in order to consider the given flow limits Qmin and Qmax while the complete regulation process. In Spaix it is very easy to indicate different duty points and to adapt the pump performance curve accordingly. Beside the speed adaptation as used in the example the software supports the curve conversion for impeller trimming, for changing of blade angle of propeller pumps as well as through throttling. For the transport of high-viscosity fluids conversion procedure of the Hydraulic Institute is implemented.

“For the application in our enterprise especially the different calculation opportunities are in priority” reports Hans-Georg Behninger, responsible for the pump selection at the Engineering of Degussa AG. “In connection with the project interface for data exchange to the pump manufacturers we can streamline our working processes in the future. Furthermore we can achieve significant time and cost savings in the planning and procurement. First field tests ended successfully. The production phase with a well-known pump manufacturer begins soon.”

The pump manufacturer can read in the project data into Spaix or another program that supports the VDMA norm. The complete configuration of all components with the appropriate price calculation in Spaix results very quickly in a complete quotation. The individual designable data sheets can be adapted to the Corporate Design or the form instructions of the customer.

About Spaix

The Spaix® product family provides suitable software solutions for the selection and configuration of centrifugal pumps and complete pump assemblies. Spaix increases enormously the quickness and the technical quality of the processing of customer inquiries, of the selection and configuration of pump stations as well as the quotation. The software system is available for Windows AND Internet.

About VSX – VOGEL SOFTWARE

VSX – VOGEL SOFTWARE is the specialist for software and internet solutions for the pump industry. The company is the market leader for pump selection software and develops applications for the selection and calculation of technical components and systems.

Source: VSX – VOGEL SOFTWARE GmbH